A maintenance engineer career is something you should consider if your qualifications are correct. Here are some of these certifications and the expected earnings. Maintenance engineers are a job that is perfect for those who have a keen eye for detail. They are responsible for maintaining the building's infrastructure and ensuring that it operates at its best.

Qualifications for a career in maintenance engineering

These are the key elements to consider if you are looking for a career as an engineer in maintenance. While a high school diploma will provide the foundational skills you need, you can also consider taking a college course in engineering. As well as work experience, courses in chemistry or math are beneficial. A technical school may be an option depending on the needs and interests of your company.

Maintenance engineers are responsible for maintaining machinery and equipment as well as infrastructures, systems, and systems. Their job is to keep industrial machinery operating as efficiently as possible. They are responsible for ensuring that spare parts and supplies are available. Certain jobs in this sector require working shifts, especially in manufacturing. Depending on what type of work they do, maintenance engineers could move up to management positions or seek other opportunities in related fields. After they have gained experience, they may be able to start their own business.

Maintenance engineers make between PS20,000 to PS25,000 an average. The salary of maintenance engineers can vary depending upon the industry, the location and the size of the company. An engineer who is skilled in maintenance can be promoted to management positions. A Chartered status can also assist with career advancement.

Certifications are required

Maintenance engineers may require multiple certifications. These certifications can be specific or general in nature. They may also cover hazardous materials handling. The International Maintenance Institute offers professional certification in several levels. There are lower-level certifications available for Certified Maintenance Technicians. Certifications that can be used to become Maintenance Managers or Certified Maintenance Professionals are also available.

Consider your educational background before you consider becoming a maintenance technician. Most certification providers do not require specific educational qualifications. However, some recommend high school diplomas or GEDs. Most employers and recruiters require this minimum qualification. If you have work experience in a related industry, however, you can still obtain certification.

Although a bachelor's degree does not necessarily mean you can become a maintenance engineer or vice versa, a degree in a relevant field will make you stand out among the rest. It is possible to get a degree in electrical, mechanical, or facilities management. Even if you don’t have an engineering degree you might still be able to work as a maintenance technie or progress to the position of maintenance engineer through training and experience.

Salary

The Bureau of Labor Statistics has no control over the salaries of maintenance professionals, but there is expected to be growth in other related fields. In general maintenance, engineers and mechanical technicians are expected to see eight percent growth, while construction management managers might see an 11 percent increase in their employment. Therefore, if you're considering a career as a maintenance engineer, you should focus on industries with high job growth, or look for entry-level positions within those industries.

Maintenance engineer salary: The 2008 median maintenance engineer salary was $88,570. The lowest 25 % earned $48,270, and the highest 10 % earned more that $110,310.

FAQ

What are my options for learning more about manufacturing

Hands-on experience is the best way to learn more about manufacturing. But if that is not possible you can always read books and watch educational videos.

Why automate your warehouse

Modern warehousing is becoming more automated. With the rise of ecommerce, there is a greater demand for faster delivery times as well as more efficient processes.

Warehouses should be able adapt quickly to new needs. To do so, they must invest heavily in technology. Automation of warehouses offers many benefits. Here are some of the reasons automation is worth your investment:

-

Increases throughput/productivity

-

Reduces errors

-

Increases accuracy

-

Safety is boosted

-

Eliminates bottlenecks

-

This allows companies to scale easily

-

Workers are more productive

-

This gives you visibility into what happens in the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

Minimizes downtime and increases uptime

-

You can be sure that high-quality products will arrive on time

-

Eliminates human error

-

Helps ensure compliance with regulations

What are manufacturing and logistics?

Manufacturing refers to the process of making goods using raw materials and machines. Logistics includes all aspects related to supply chain management, such as procurement, distribution planning, inventory control and transportation. Logistics and manufacturing are often referred to as one thing. It encompasses both the creation of products and their delivery to customers.

Why is logistics important in manufacturing?

Logistics are an essential component of any business. They are essential to any business's success.

Logistics play an important role in reducing costs as well as increasing efficiency.

What does manufacturing industry mean?

Manufacturing Industries are businesses that produce products for sale. These products are sold to consumers. These companies employ many processes to achieve this purpose, such as production and distribution, retailing, management and so on. They produce goods from raw materials by using machines and other machinery. This includes all types if manufactured goods.

What is it like to manage a logistics company?

You need to have a lot of knowledge and skills to manage a successful logistic business. For clients and suppliers to be successful, you need to have excellent communication skills. You should be able analyse data and draw inferences. You must be able manage stress and pressure under pressure. You must be creative and innovative to develop new ideas to improve efficiency. Strong leadership qualities are essential to motivate your team and help them achieve their organizational goals.

It is also important to be efficient and well organized in order meet deadlines.

What are the responsibilities of a manufacturing manager

A manufacturing manager must make sure that all manufacturing processes run smoothly and effectively. They should be aware of any issues within the company and respond accordingly.

They should also be able communicate with other departments, such as sales or marketing.

They should also be aware of the latest trends in their industry and be able to use this information to help improve productivity and efficiency.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

External Links

How To

How to Use Lean Manufacturing in the Production of Goods

Lean manufacturing refers to a method of managing that seeks to improve efficiency and decrease waste. It was developed in Japan between 1970 and 1980 by Taiichi Ohno. TPS founder Kanji Tyoda gave him the Toyota Production System, or TPS award. Michael L. Watkins published the first book on lean manufacturing in 1990.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It emphasizes reducing defects and eliminating waste throughout the value chain. The five-steps of Lean Manufacturing are just-in time (JIT), zero defect and total productive maintenance (TPM), as well as 5S. Lean manufacturing eliminates non-value-added tasks like inspection, rework, waiting.

Lean manufacturing can help companies improve their product quality and reduce costs. Additionally, it helps them achieve their goals more quickly and reduces employee turnover. Lean Manufacturing is one of the most efficient ways to manage the entire value chains, including suppliers and customers as well distributors and retailers. Many industries worldwide use lean manufacturing. Toyota's philosophy has been a key driver of success in many industries, including automobiles and electronics.

Five fundamental principles underlie lean manufacturing.

-

Define Value - Determine the value that your business brings to society. Also, identify what sets you apart from your competitors.

-

Reduce Waste – Eliminate all activities that don't add value throughout the supply chain.

-

Create Flow – Ensure that work flows smoothly throughout the process.

-

Standardize and simplify - Make your processes as consistent as possible.

-

Build Relationships - Establish personal relationships with both internal and external stakeholders.

Lean manufacturing is not a new concept, but it has been gaining popularity over the last few years due to a renewed interest in the economy following the global financial crisis of 2008. Many businesses are now using lean manufacturing to improve their competitiveness. In fact, some economists believe that lean manufacturing will be an important factor in economic recovery.

With many benefits, lean manufacturing is becoming more common in the automotive industry. These include improved customer satisfaction, reduced inventory levels, lower operating costs, increased productivity, and better overall safety.

You can apply Lean Manufacturing to virtually any aspect of your organization. It is especially useful for the production aspect of an organization, as it ensures that every step in the value chain is efficient and effective.

There are three main types of lean manufacturing:

-

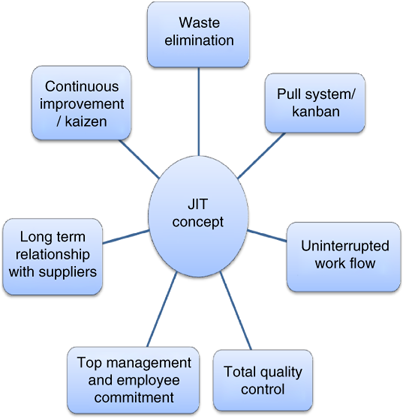

Just-in Time Manufacturing, (JIT): This kind of lean manufacturing is also commonly known as "pull-systems." JIT stands for a system where components are assembled on the spot rather than being made in advance. This strategy aims to decrease lead times, increase availability of parts and reduce inventory.

-

Zero Defects Manufacturing - ZDM: ZDM focuses its efforts on making sure that no defective units leave a manufacturing facility. If a part needs to be fixed during the assembly line, it should be repaired rather than scrapped. This applies to finished goods that may require minor repairs before shipment.

-

Continuous Improvement (CI), also known as Continuous Improvement, aims at improving the efficiency of operations through continuous identification and improvement to minimize or eliminate waste. Continuous improvement involves continuous improvement of processes and people as well as tools.