Lean manufacturing refers to a method of managing that reduces waste and increases efficiency. It is based upon the philosophies of Henry Ford & KiichiroToyoda, who were presidents and CEOs of Toyota Motor Corporation in the years before World War II. Manufacturing is not only an assembly line, but a system. Lean manufacturing considers it to be a whole system. Lean is based on five principles: reduce waste; streamline the process; create knowledge; optimize the whole; and use continuous improvement.

To become lean, the first step is to find out what you're doing that doesn't add value. This can be done with quantitative or qualitative techniques. One example is to look at what your customers pay for your product. If the price of your product is higher than what you are offering, that's a sign you have a problem.

Kaizen is a method to identify the amount of waste produced by a process. This involves everyone in the organization working together to solve problems on an incremental basis. Kaizen events are a combination of other lean tools and can be used by themselves or with others.

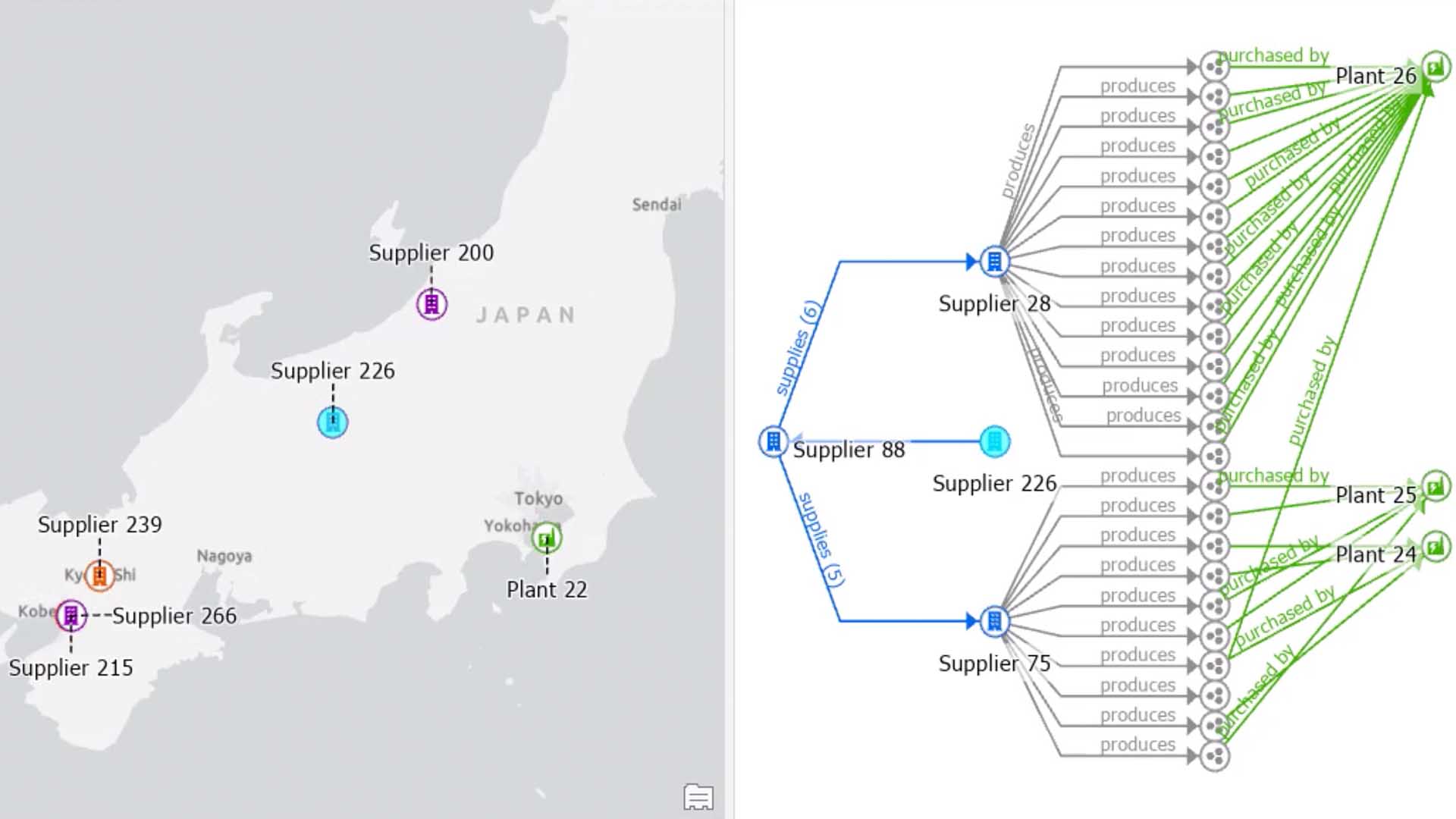

Value stream mapping is another way to identify production waste. VSM is a way for manufacturers to see the production steps and determine which are the most time-consuming.

Waste areas include inventory, waiting, overproduction, motion, and defects. To identify areas where improvement can be made, a lean team will map these areas. They could be part of the supply chain or in a production zone, or all throughout the process.

Once the waste has been identified, you can start implementing strategies to eliminate it. These include creating crossfunctional teams and flattening your workload. You can also train your employees to multi-skilled. Depending on your business, you may want to implement technologies like just-in-time or cellular manufacturing. Other lean tools, such as total production maintenance or kanban management, can be used.

A system of standardized containers can be integrated to allow workers to count exact quantities. Standardized containers allow workers to easily detect whether food or other items are mixed in the products. Also, safety mats can be installed near machine areas that trigger a stoppage when a person steps on them.

As with any lean initiative, it is important to have an organizational culture. The culture should include communication skills, understanding the goal, and a longterm focus. It is crucial to create a sustainable improvement system in your company for its success.

You can use value stream mapping to help you decide on a new machine. This will allow you to create an inventory that can include the future condition of your products and raw materials as well as customer needs. This information will allow you to predict when supplies and equipment will be needed. Similarly, you can create a scheduling system to ensure you can fulfill orders on time.

By incorporating the five key principles of lean manufacturing, you can improve your organization's efficiency and help you achieve your goals. Learn more about the various techniques and resources you have at your disposal on lean manufacturing websites.

FAQ

What are the products of logistics?

Logistics refers to the movement of goods from one place to another.

These include all aspects related to transport such as packaging, loading and transporting, storing, transporting, unloading and warehousing inventory management, customer service. Distribution, returns, recycling are some of the options.

Logisticians ensure that the product is delivered to the correct place, at the right time, and under safe conditions. They provide information on demand forecasts as well stock levels, production schedules and availability of raw material.

They can also track shipments in transit and monitor quality standards.

What is the distinction between Production Planning or Scheduling?

Production Planning (PP), is the process of deciding what production needs to take place at any given time. Forecasting and identifying production capacity are two key elements to this process.

Scheduling refers the process by which tasks are assigned dates so that they can all be completed within the given timeframe.

How can manufacturing efficiency be improved?

First, we need to identify which factors are most critical in affecting production times. We must then find ways that we can improve these factors. If you don’t know how to start, look at which factors have the greatest impact upon production time. Once you have identified them, it is time to identify solutions.

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

How to use the Just In-Time Production Method

Just-in time (JIT), is a process that reduces costs and increases efficiency in business operations. It is a process where you get the right amount of resources at the right moment when they are needed. This means that only what you use is charged to your account. Frederick Taylor, a 1900s foreman, first coined the term. After observing how workers were paid overtime for late work, he realized that overtime was a common practice. He decided to ensure workers have enough time to do their jobs before starting work to improve productivity.

JIT is about planning ahead. You should have all the necessary resources ready to go so that you don’t waste money. The entire project should be looked at from start to finish. You need to ensure you have enough resources to tackle any issues that might arise. You'll be prepared to handle any potential problems if you know in advance. This way you won't be spending more on things that aren’t really needed.

There are many types of JIT methods.

-

Demand-driven: This type of JIT allows you to order the parts/materials required for your project on a regular basis. This will allow to track how much material has been used up. This will allow you to calculate how long it will take to make more.

-

Inventory-based: You stock materials in advance to make your projects easier. This allows you predict the amount you can expect to sell.

-

Project-driven : This is a method where you make sure that enough money is set aside to pay the project's cost. You will be able to purchase the right amount of materials if you know what you need.

-

Resource-based JIT is the most widespread form. You allocate resources based on the demand. For instance, if you have a lot of orders coming in, you'll assign more people to handle them. You'll have fewer orders if you have fewer.

-

Cost-based: This is similar to resource-based, except that here you're not just concerned about how many people you have but how much each person costs.

-

Price-based: This approach is very similar to the cost-based method except that you don't look at individual workers costs but the total cost of the company.

-

Material-based is an alternative to cost-based. Instead of looking at the total cost in the company, this method focuses on the average amount of raw materials that you consume.

-

Time-based: This is another variation of resource-based JIT. Instead of focusing only on how much each employee is costing, you should focus on how long it takes to complete your project.

-

Quality-based JIT: This is another variation of resource based JIT. Instead of worrying about the costs of each employee or how long it takes for something to be made, you should think about how quality your product is.

-

Value-based JIT : This is the newest type of JIT. In this scenario, you're not concerned about how products perform or whether customers expect them to meet their expectations. Instead, your focus is on the value you bring to the market.

-

Stock-based is an inventory-based system that measures the number of items produced at any given moment. This is used to increase production and minimize inventory.

-

Just-intime (JIT), planning is a combination JIT management and supply chain management. This refers to the scheduling of the delivery of components as soon after they are ordered. It is essential because it reduces lead-times and increases throughput.