Considering the many articles published on supply chain management, the question is, what are the most cited? The topic is covered in a lot of academic research, so this is not an easy question. However, one can narrow down the field using cocitation analysis. We used the cocitation of the Supply Chain Management Association database to uncover the most frequently cited articles in supply chain management. The International Journal of Supply Chain Management was the top-ranked journal with 25,476 citations. Based on the most read article, the citations were divided into five groups. Because International Journal of Supply Chain Management is more cited than most journals, it's difficult to predict which order the citations will appear.

Amazon's supply chain practices are the most widely cited article and the one that best reflects the research. Amazon is a company that connects buyers and sellers. This review will reveal what works and what does not. The article discusses Amazon's many pitfalls, as well as the opportunities it offers. It also suggests several actionable ways to remedy these shortcomings.

Cross-sectional studies of supply chain risk and performance are the most popular. Regression and panel data are used to determine the effect of supply risks on performance. This is no small feat. These results are stunning. It is clear that supply chain risk management is the best approach to improving performance over the long term. This also has implications for other areas in corporate life such as procurement or customer service.

Not all notable accomplishments of the same calibre are the most frequently cited. It is not surprising that the journal with the highest citations has the most publications in the Supply Chain Management Association's database. The International Journal of Supply Chain Management (the flagship journal of Supply Chain Management Association) has the highest number of citations with 25,476. This is more that twice the number of citations received by the Supply Chain Management Association's sister publication, International Journal of Logistics Research and Applications.

FAQ

What does warehouse refer to?

A warehouse or storage facility is where goods are stored before they are sold. It can be indoors or out. It may also be an indoor space or an outdoor area.

How can excess manufacturing production be reduced?

It is essential to find better ways to manage inventory to reduce overproduction. This would reduce the time needed to manage inventory. This could help us free up our time for other productive tasks.

One way to do this is to adopt a Kanban system. A Kanban Board is a visual display that tracks work progress. Kanban systems are where work items travel through a series of states until reaching their final destination. Each state represents a different priority.

For instance, when work moves from one stage to another, the current task is complete enough to be moved to the next stage. A task that is still in the initial stages of a process will be considered complete until it moves on to the next stage.

This allows you to keep work moving along while making sure that no work gets neglected. Managers can monitor the work being done by Kanban boards to see what is happening at any given time. This information allows them to adjust their workflow based on real-time data.

Another way to control inventory levels is to implement lean manufacturing. Lean manufacturing works to eliminate waste throughout every stage of the production chain. Anything that does nothing to add value to a product is waste. Here are some examples of common types.

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Overstock materials

Manufacturers can increase efficiency and decrease costs by implementing these ideas.

What is the distinction between Production Planning or Scheduling?

Production Planning (PP), also known as forecasting and identifying production capacities, is the process that determines what product needs to be produced at any particular time. Forecasting demand is one way to do this.

Scheduling is the process that assigns dates to tasks so they can get completed within a given timeframe.

Why is logistics important for manufacturing?

Logistics are an integral part any business. They enable you to achieve outstanding results by helping manage product flow from raw materials through to finished goods.

Logistics are also important in reducing costs and improving efficiency.

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

How to use lean manufacturing in the production of goods

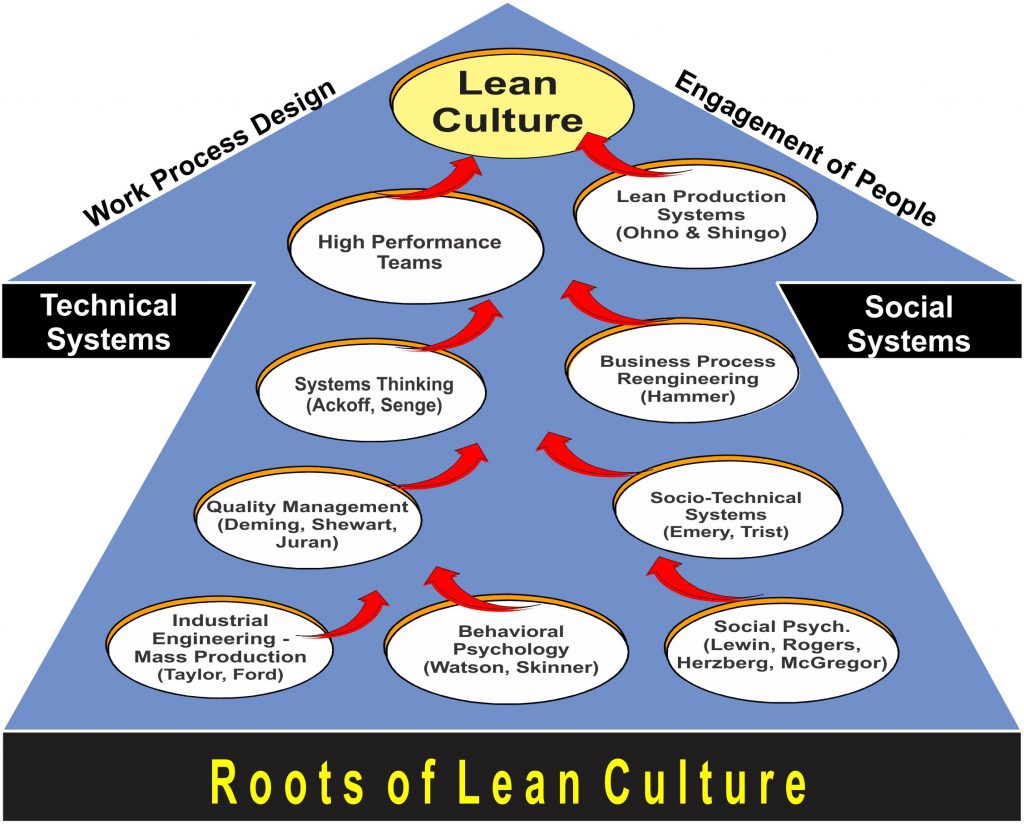

Lean manufacturing (or lean manufacturing) is a style of management that aims to increase efficiency, reduce waste and improve performance through continuous improvement. It was developed in Japan between 1970 and 1980 by Taiichi Ohno. TPS founder Kanji Tyoda gave him the Toyota Production System, or TPS award. Michael L. Watkins published the book "The Machine That Changed the World", which was the first to be published about lean manufacturing.

Lean manufacturing, often described as a set and practice of principles, is aimed at improving the quality, speed, cost, and efficiency of products, services, and other activities. It emphasizes reducing defects and eliminating waste throughout the value chain. Lean manufacturing is called just-in-time (JIT), zero defect, total productive maintenance (TPM), or 5S. Lean manufacturing focuses on eliminating non-value-added activities such as rework, inspection, and waiting.

Lean manufacturing improves product quality and costs. It also helps companies reach their goals quicker and decreases employee turnover. Lean manufacturing can be used to manage all aspects of the value chain. Customers, suppliers, distributors, retailers and employees are all included. Lean manufacturing practices are widespread in many industries. Toyota's philosophy has been a key driver of success in many industries, including automobiles and electronics.

Five fundamental principles underlie lean manufacturing.

-

Define Value - Determine the value that your business brings to society. Also, identify what sets you apart from your competitors.

-

Reduce Waste - Remove any activity which doesn't add value to your supply chain.

-

Create Flow. Ensure that your work is uninterrupted and flows seamlessly.

-

Standardize and simplify - Make your processes as consistent as possible.

-

Building Relationships – Establish personal relationships with both external and internal stakeholders.

Lean manufacturing, although not new, has seen renewed interest in the economic sector since 2008. Many companies have adopted lean manufacturing methods to increase their marketability. Economists think that lean manufacturing is a crucial factor in economic recovery.

Lean manufacturing is becoming a popular practice in automotive. It has many advantages. These include better customer satisfaction and lower inventory levels. They also result in lower operating costs.

Any aspect of an enterprise can benefit from Lean manufacturing. This is because it ensures efficiency and effectiveness in all stages of the value chain.

There are three main types of lean manufacturing:

-

Just-in-Time Manufacturing: Also known as "pull systems", this type of lean manufacturing uses just-in-time manufacturing (JIT). JIT means that components are assembled at the time of use and not manufactured in advance. This approach aims to reduce lead times, increase the availability of parts, and reduce inventory.

-

Zero Defects Manufacturing (ZDM): ZDM focuses on ensuring that no defective units leave the manufacturing facility. You should repair any part that needs to be repaired during an assembly line. This also applies to finished products that need minor repairs before being shipped.

-

Continuous Improvement: Continuous Improvement aims to improve efficiency by continually identifying problems and making adjustments to eliminate or minimize waste. It involves continuous improvement of processes, people, and tools.