The interdisciplinary field called mechanics combines mechanical engineering and electrical engineering. This combination is critical to creating advanced machines that work efficiently. A typical mechatronic system consists of sensors, actuators, and electronics. It collects signals from the environment, processes them, and generates an output signal. This system can be found on many different products. Household items such as televisions and computers have mechatronic systems installed to make them work. Mechatronic systems that can be smarter or simpler are what the electromechanical field will look like in the future.

The first electromechanical devices were used in early telegraphy. A Strowger switch was one the first electromechanical devices to send electric signals. These devices were extensively used in automated telephone networks in the United States by the middle of twentieth century. Today, more equipment is designed with automated features and the use of solid-state electronics has replaced electromechanical devices in many applications.

An Electro-mechanical Technician is a person who uses both mechanical technology and electronic circuits to maintain and operate automated equipment. They may work on energy projects or maintain equipment for deep-ocean exploration. They may also be responsible for repairs to machines. An Electro-Mechanical Technician must have excellent mechanical and troubleshooting skills as well as logical-thinking skills. They also have to be able handle pressure. They also need to be able to use tools safely. Employers may find their knowledge of electrical and mechanical systems to be very beneficial.

The diploma or certificate that Electro-mechanical Technicians can earn from technical or vocational schools is a diploma. They could also get an associate's/bachelor's in Electrical Engineering or Mechatronics. Certified Control Systems, an additional certification for Electro-mechanical technicians, is a way to show professionalism.

Electro-Mechanical Technicians may also be called assemblers. They use assembly drawings and verbal instructions to assemble electronic or mechanical equipment. They may also work with production drawings. These types assemblers are more likely need transistors.

In the coming years, mechanical engineering is expected to become more popular. Its popularity can be attributed to the societal need for more efficient and highly functional products. Many areas remain unexplored in the field of Mechatronics. These include the development new technology like particle electromechanics or the relationships between magnetic and fluid energy. Mechatronics combines both electrical engineering and computer sciences to find new solutions for problems. In addition, many large manufacturing companies are looking to develop new electronic-mechanical engineering technologies.

The field of mechanics can be very dynamic and always in flux. An Electro-mechanical Technician can choose to specialize in the field Mechatronics. This requires specialized knowledge in circuits, sensing, and software. They will be expected to apply their specialized knowledge in order to design products that add value.

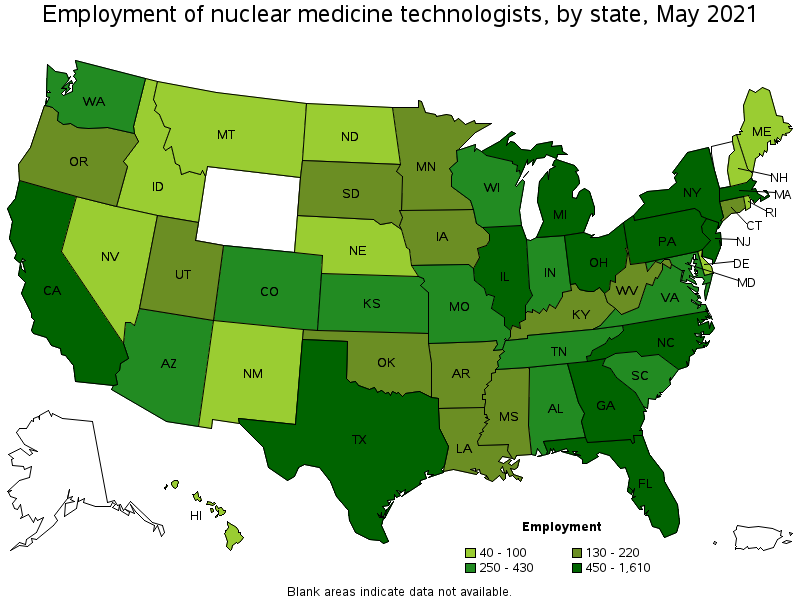

An option for electro-mechanical technicians is to choose to concentrate on industrial maintenance or Mechatronics. This type of technician is expected to remain in demand because of the growth of computer-control systems. Compensation will vary depending on where you are located, what industry you work in, and how much experience you have.

FAQ

Why automate your warehouse

Modern warehousing is becoming more automated. E-commerce has increased the demand for quicker delivery times and more efficient processes.

Warehouses must be able to quickly adapt to changing demands. In order to do this, they need to invest in technology. The benefits of automating warehouses are numerous. These are just a few reasons to invest in automation.

-

Increases throughput/productivity

-

Reduces errors

-

Increases accuracy

-

Safety Boosts

-

Eliminates bottlenecks

-

Companies can scale more easily

-

Makes workers more efficient

-

It gives visibility to everything that happens inside the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

This reduces downtime while increasing uptime

-

Ensures quality products are delivered on time

-

Eliminates human error

-

Helps ensure compliance with regulations

What can I do to learn more about manufacturing?

You can learn the most about manufacturing by getting involved in it. However, if that's not possible, you can always read books or watch educational videos.

What are the requirements to start a logistics business?

You need to have a lot of knowledge and skills to manage a successful logistic business. Effective communication skills are necessary to work with suppliers and clients. You need to understand how to analyze data and draw conclusions from it. You need to be able work under pressure and manage stressful situations. To increase efficiency and creativity, you need to be creative. To motivate and guide your team towards reaching organizational goals, you must have strong leadership skills.

It is also important to be efficient and well organized in order meet deadlines.

What is the job of a logistics manger?

A logistics manager ensures that all goods are delivered on time and without damage. This is achieved by using their knowledge and experience with the products of the company. He/she should also ensure enough stock is available to meet demand.

Statistics

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

External Links

How To

How to Use the 5S to Increase Productivity In Manufacturing

5S stands as "Sort", Set In Order", Standardize", Separate" and "Store". Toyota Motor Corporation developed the 5S method in 1954. It allows companies to improve their work environment, thereby achieving greater efficiency.

This method aims to standardize production processes so that they are repeatable, measurable and predictable. This means that daily tasks such as cleaning and sorting, storage, packing, labeling, and packaging are possible. This knowledge allows workers to be more efficient in their work because they are aware of what to expect.

There are five steps that you need to follow in order to implement 5S. Each step has a different action and leads to higher efficiency. By sorting, for example, you make it easy to find the items later. When you set items in an order, you put items together. Next, organize your inventory into categories and store them in containers that are easily accessible. Make sure everything is correctly labeled when you label your containers.

This requires employees to critically evaluate how they work. Employees should understand why they do the tasks they do, and then decide if there are better ways to accomplish them. To be successful in the 5S system, employees will need to acquire new skills and techniques.

The 5S method increases efficiency and morale among employees. As they begin to see improvements, they feel motivated to continue working towards the goal of achieving higher levels of efficiency.