Lean services applies lean manufacturing principles to the service sector. Companies that have adopted this approach to their production processes include health care providers in the US and HMRC in the UK. Lean services are intended to reduce waste and increase customer satisfaction while reducing costs. Lean services are available to all businesses, regardless of whether they're small startups or global giants.

Lean manufacturing

Lean manufacturing is a process that is based on eliminating waste. The process helps businesses increase their overall productivity, reduce operating costs, and increase employee satisfaction. Ultimately, it can increase profits. It can reduce the time it takes to produce a product, and increase profits. Lean manufacturing services can also help companies increase their customer base and revenue streams.

Lean manufacturing demands a team approach and a lot more talent. It is vital that everyone on the team knows the process. They should also be able to adapt the processes to meet the needs of their organization. Simpler manufacturing processes are the first step of lean manufacturing. Complex manufacturing processes can make it difficult for people to spot inefficiencies and waste. Simpler processes allow for better visibility and encourage continuous improvement. This will allow your employees the freedom to search for inefficiencies.

Lean manufacturing services can help companies improve their efficiency by reducing their lead time. MXGlobal, one of these companies that offers lean implementation has successfully consulted Japanese firms with a U.S. present. The firm's services in lean manufacturing are designed to aid businesses worldwide and help them achieve their business goals.

Lean manufacturing services are designed to help businesses create an environment that maximizes profits. They are focused on improving productivity and reducing waste. There are eight types. They include wastes from overproduction, inventory, defects, and transportation. These wastes could increase costs or decrease customer satisfaction.

Management of lean operations

To implement lean operations management for lean services, organizations must first determine what they are trying to achieve. As the name implies, it is a systematic approach that seeks to create value for the end customers. This is what customers expect from a product/service. Value is what drives sales. Start by mapping the various steps involved in the creation of a product/service and asking, "What adds to the customer?"

Lean management is about continuous improvement. Continuous improvement is the main step in this process. It will ensure that your team is able to deliver work assignments on time and with minimal effort. Additionally, it reduces waste and optimizes overhead costs. Lean management's four principles include continuous improvement, minimizing waste and reducing cycle times. They also ensure continuous workflows.

Lean operations management in lean services is focused on creating more value and utilizing fewer resources. It is more difficult to identify intangible wastes in a service environment. But lean principles aim to reduce and eliminate them. Companies can increase their customer value and maximize profits by eliminating waste.

FAQ

What is the best way to learn about manufacturing?

Hands-on experience is the best way to learn more about manufacturing. You can read books, or watch instructional videos if you don't have the opportunity to do so.

How can manufacturing avoid production bottlenecks

You can avoid bottlenecks in production by making sure that everything runs smoothly throughout the production cycle, from the moment you receive an order to the moment the product is shipped.

This includes planning for capacity requirements as well as quality control measures.

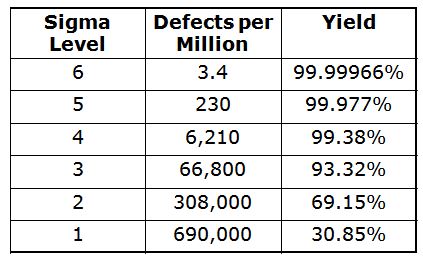

Continuous improvement techniques such Six Sigma can help you achieve this.

Six Sigma can be used to improve the quality and decrease waste in all areas of your company.

It focuses on eliminating variation and creating consistency in your work.

What type of jobs is there in logistics

Logistics can offer many different jobs. Some of them are:

-

Warehouse workers - They load and unload trucks and pallets.

-

Transport drivers - These are people who drive trucks and trailers to transport goods or perform pick-ups.

-

Freight handlers - They sort and pack freight in warehouses.

-

Inventory managers - They oversee the inventory of goods in warehouses.

-

Sales representatives - They sell products.

-

Logistics coordinators - They plan and organize logistics operations.

-

Purchasing agents are those who purchase goods and services for the company.

-

Customer service representatives are available to answer customer calls and emails.

-

Shippers clerks - They process shipping order and issue bills.

-

Order fillers – They fill orders based upon what was ordered and shipped.

-

Quality control inspectors: They inspect outgoing and incoming products for any defects.

-

Others - There is a variety of other jobs in logistics. These include transportation supervisors and cargo specialists.

Is it possible to automate certain parts of manufacturing

Yes! Yes. The Egyptians created the wheel thousands years ago. Today, robots assist in the assembly of lines.

Actually, robotics can be used in manufacturing for many purposes. These include:

-

Automation line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

Automation could also be used to improve manufacturing. For example, 3D printing allows us to make custom products without having to wait for weeks or months to get them manufactured.

What skills are required to be a production manager?

A production planner must be organized, flexible, and able multitask to succeed. You must also be able to communicate effectively with clients and colleagues.

What is the responsibility of a manufacturing manager?

A manufacturing manager has to ensure that all manufacturing processes work efficiently and effectively. They must also be alert to any potential problems and take appropriate action.

They should also be able and comfortable communicating with other departments like sales and marketing.

They should be up to date on the latest trends and be able apply this knowledge to increase productivity and efficiency.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

External Links

How To

How to use Lean Manufacturing in the production of goods

Lean manufacturing is a management style that aims to increase efficiency and reduce waste through continuous improvement. It was developed by Taiichi Okono in Japan, during the 1970s & 1980s. TPS founder Kanji Takoda awarded him the Toyota Production System Award (TPS). Michael L. Watkins published the first book on lean manufacturing in 1990.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It emphasizes the elimination and minimization of waste in the value stream. Lean manufacturing can be described as just-in–time (JIT), total productive maintenance, zero defect (TPM), or even 5S. Lean manufacturing eliminates non-value-added tasks like inspection, rework, waiting.

Lean manufacturing not only improves product quality but also reduces costs. Companies can also achieve their goals faster by reducing employee turnover. Lean manufacturing is a great way to manage the entire value chain including customers, suppliers, distributors and retailers as well as employees. Lean manufacturing practices are widespread in many industries. Toyota's philosophy has been a key driver of success in many industries, including automobiles and electronics.

Five principles are the basis of lean manufacturing:

-

Define Value- Identify the added value your company brings to society. What makes you stand out from your competitors?

-

Reduce Waste - Eliminate any activity that doesn't add value along the supply chain.

-

Create Flow. Ensure that your work is uninterrupted and flows seamlessly.

-

Standardize & simplify - Make processes consistent and repeatable.

-

Build Relationships- Develop personal relationships with both internal as well as external stakeholders.

Although lean manufacturing has always been around, it is gaining popularity in recent years because of a renewed interest for the economy after 2008's global financial crisis. Many businesses have adopted lean production techniques to make them more competitive. Economists think that lean manufacturing is a crucial factor in economic recovery.

With many benefits, lean manufacturing is becoming more common in the automotive industry. These include higher customer satisfaction levels, reduced inventory levels as well as lower operating costs.

Any aspect of an enterprise can benefit from Lean manufacturing. However, it is particularly useful when applied to the production side of an organization because it ensures that all steps in the value chain are efficient and effective.

There are three types principally of lean manufacturing:

-

Just-in Time Manufacturing (JIT), also known as "pull system": This form of lean manufacturing is often referred to simply as "pull". JIT means that components are assembled at the time of use and not manufactured in advance. This approach aims to reduce lead times, increase the availability of parts, and reduce inventory.

-

Zero Defects Manufacturing - ZDM: ZDM focuses its efforts on making sure that no defective units leave a manufacturing facility. If a part needs to be fixed during the assembly line, it should be repaired rather than scrapped. This also applies to finished products that need minor repairs before being shipped.

-

Continuous Improvement: Continuous Improvement aims to improve efficiency by continually identifying problems and making adjustments to eliminate or minimize waste. Continuous improvement involves continuous improvement of processes and people as well as tools.