The average engineer salary can vary greatly depending on where you reside. The highest-paid state in the United States is Washington, followed closely by New York and California. It is also important to take into account the cost of living in a new place. A salary of $96,640 might not be enough to cover your daily expenses. It is crucial to assess your cost of living before applying for a new job.

The median salary for an electrical engineer is $96,640

According to the U.S. Bureau of Labor Statistics the average salary of an electrical engineer is $96,640 annually. This number may differ from one state to another. The salaries of different industry sectors can vary significantly. Retail trade is the most lucrative industry for electrical engineers, while education services is the lowest paying. It is important to remember that there are many factors that go into determining the average annual salary of an electrical engineer. Below is a breakdown showing the different salary levels of electrical engineers.

Electricians are responsible to design and develop electrical equipment. They are also responsible for the design and development of electrical equipment. This statistic includes salaries of all types, but not Computer Hardware Engineers. Computer Hardware Engineers are those who create computers. According to the Bureau of Labor Statistics in 2026, these professionals are expected to grow by 7 percent. Most electrical engineers will work in offices, though they may also travel to different types of sites for field work.

Biomedical engineers make a median income of $89 130

Biomedical engineer combine their engineering knowledge with knowledge about the human body to design medical devices. Their backgrounds in biomechanics help them understand how different medical devices work and interact with the human body. This knowledge can be used to create artificial organs, medical devices, and diagnostic tools.

In addition to applying engineering principles to medical procedures, biomedical engineers are expected to have excellent communication skills. They are expected to communicate with other health care professionals, present research results and publish scientific papers. A high level of mathematics proficiency is required.

Median salary for mechanical engineers: $91,352

Multiple factors influence the salary of a mechanical engineer. For example, salaries vary by location and industry. According to ASME members' 2017 Salary Survey, those in the Northeast and Southwest have higher salaries than others. The Midwest earns less than those who work there.

The range of salaries for mechanical engineers is $91,352 to $123,028. The average salary is $91,352, with the top sixth of engineers earning more than the median. Those earning less than two years of experience earn an average of $72,400. However, people with 20 years experience can make as much as $150,000

Agricultural engineers earn a median salary of $89,130

Agricultural engineers work in agricultural settings to help solve problems related to environmental and power supplies. They oversee construction and participate in design. This profession requires advanced engineering skills and knowledge of the sciences, including biology and math. They earn comparable salaries to similar occupations in the United States. They typically make less than naval architects or locomotive engineers. The outlook is positive for agricultural engineers. The employment rate will increase by 7.4% between 2016-2026.

The median salary for agricultural engineers in the U.S. is $89,130, with the highest-paid individuals earning more than $110,000. The median agricultural engineer salary varies from one location to the next. Santa Clara (San Francisco) and Bolinas are among the top-paying cities for agricultural engineers.

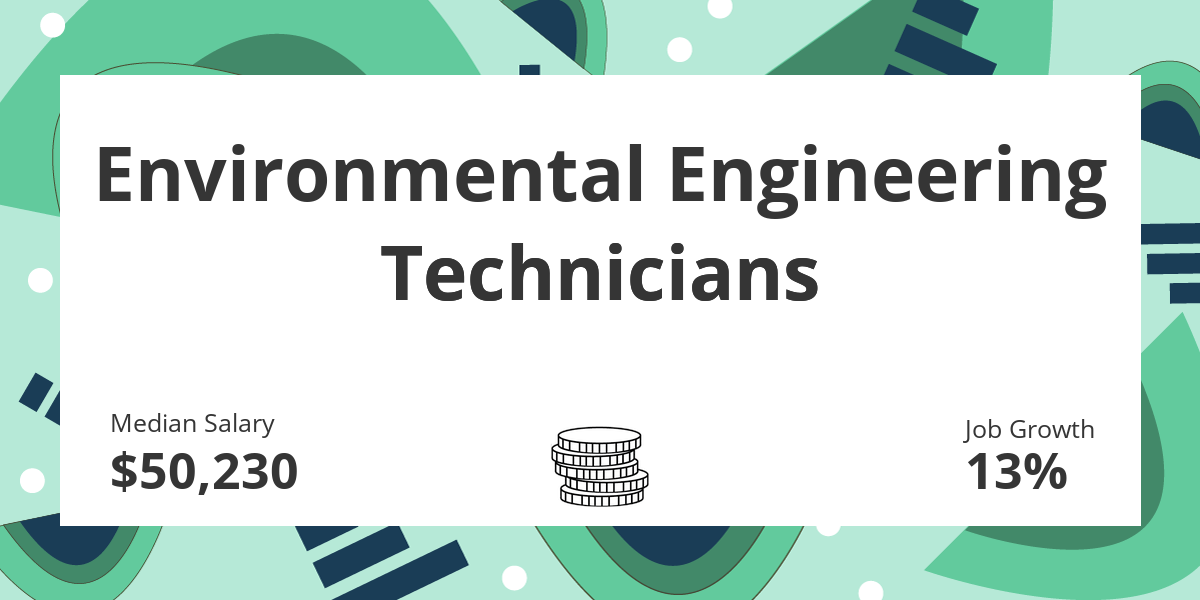

The median salary for environmental engineers is $87,620

Environmental engineers work to protect the environment from damage by developing and implementing solutions to minimize negative effects. They may work in multiple fields and collaborate closely with other engineers, such construction managers or urban planners. They are trained in biology, chemistry, data analysis, and critical thinking. They help organizations comply with regulations and also have a good understanding of environmental law.

Therefore, environmental engineers need to be adaptable and flexible to change technologies and best practice. They also need to have advanced analytical skills and the ability to collaborate with their team. They must also be problem-solvers with a positive outlook.

FAQ

What is the difference between Production Planning and Scheduling?

Production Planning (PP) is the process of determining what needs to be produced at any given point in time. This can be done by forecasting demand and identifying production capabilities.

Scheduling refers the process by which tasks are assigned dates so that they can all be completed within the given timeframe.

What are the 7 R's of logistics?

The acronym "7R's" of Logistics stands for seven principles that underpin logistics management. It was published in 2004 by the International Association of Business Logisticians as part of their "Seven Principles of Logistics Management" series.

The acronym is composed of the following letters.

-

Responsible - ensure that actions are in compliance with legal requirements and do not cause harm to others.

-

Reliable – have faith in your ability and capability to keep promises.

-

Be responsible - Use resources efficiently and avoid wasting them.

-

Realistic – consider all aspects of operations, from cost-effectiveness to environmental impact.

-

Respectful - show respect and treat others fairly and fairly

-

Resourceful - look for opportunities to save money and increase productivity.

-

Recognizable - Provide value-added services to customers

What is manufacturing and logistics?

Manufacturing is the act of producing goods from raw materials using machines and processes. Logistics manages all aspects of the supply chain, including procurement, production planning and distribution, inventory control, transportation, customer service, and transport. As a broad term, manufacturing and logistics often refer to both the creation and delivery of products.

What can I do to learn more about manufacturing?

You can learn the most about manufacturing by getting involved in it. However, if that's not possible, you can always read books or watch educational videos.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

How to use the Just-In Time Method in Production

Just-in-time is a way to cut costs and increase efficiency in business processes. It is a process where you get the right amount of resources at the right moment when they are needed. This means that your only pay for the resources you actually use. Frederick Taylor, a 1900s foreman, first coined the term. Taylor observed that overtime was paid to workers if they were late in working. He decided that workers would be more productive if they had enough time to complete their work before they started to work.

JIT is a way to plan ahead and make sure you don't waste any money. It is important to look at your entire project from beginning to end and ensure that you have enough resources to handle any issues that may arise. You can anticipate problems and have enough equipment and people available to fix them. This will prevent you from spending extra money on unnecessary things.

There are many JIT methods.

-

Demand-driven: This JIT is where you place regular orders for the parts/materials that are needed for your project. This will let you track the amount of material left over after you've used it. This will allow you to calculate how long it will take to make more.

-

Inventory-based: You stock materials in advance to make your projects easier. This allows you to predict how much you can expect to sell.

-

Project-driven: This approach involves setting aside sufficient funds to cover your project's costs. When you know how much you need, you'll purchase the appropriate amount of materials.

-

Resource-based JIT is the most widespread form. You allocate resources based on the demand. If you have many orders, you will assign more people to manage them. If you don’t have many orders you will assign less people to the work.

-

Cost-based: This approach is very similar to resource-based. However, you don't just care about the number of people you have; you also need to consider how much each person will cost.

-

Price-based pricing: This is similar in concept to cost-based but instead you look at how much each worker costs, it looks at the overall company's price.

-

Material-based - This is a variant of cost-based. But instead of looking at the total company cost, you focus on how much raw material you spend per year.

-

Time-based: This is another variation of resource-based JIT. Instead of focusing only on how much each employee is costing, you should focus on how long it takes to complete your project.

-

Quality-based: This is yet another variation of resource-based JIT. Instead of focusing on the cost of each worker or how long it takes, think about how high quality your product is.

-

Value-based: This is one of the newest forms of JIT. In this instance, you are not concerned about the product's performance or meeting customer expectations. Instead, you are focused on adding value to the marketplace.

-

Stock-based is an inventory-based system that measures the number of items produced at any given moment. This method is useful when you want to increase production while decreasing inventory.

-

Just-in-time (JIT) planning: This is a combination of JIT and supply chain management. It is the process that schedules the delivery of components within a short time of their order. It's important as it reduces leadtimes and increases throughput.