It is important that you include all the duties in the job description to attract the best people for transport and logistic jobs. These duties may include ordering raw materials or filling out company paperwork. Although it may make the job description sound more attractive, hiring the wrong person can lead to misplaced hires. This can cause problems for your business and customers. This means you will have to spend money and time training your new employee.

Job description

Transport and logistics professionals work in a diverse range of industries to move people and goods from point A to point B. Some may work in shipping. Other might be involved in road maintenance. Monitoring traffic congestion and product safety is part of the job. Those who work in this field are often required to adapt to changing business needs and work in various locations.

A job description that is effective focuses on the skills and training required for the job. It also reflects the company's culture, values, and culture. It should state whether the job is permanent or temporary.

Salary

Many opportunities exist in transport and logistics jobs. These range from entry-level roles to more senior positions. Salary levels vary according to experience and the type of industry you're in. The average salary for entry-level positions is $40,000 annually. However, these salaries can rise and there is room to grow.

There are many salaries available in transportation and logistics, and some jobs can be more lucrative than others. While entry-level salaries are less than in other fields, if you're a skilled worker, your earnings may be higher. Some companies offer training on-site or pay for graduate level education.

Requirements

Many industries are looking for skilled transportation and logistics workers. The main focus of these jobs is ensuring that goods are delivered safely, at the right time, and at the lowest possible cost. Therefore, it is important for companies that they recruit the right staff. Although junior staff do not require any training, senior staff should have the appropriate qualifications such as a Supply Chain Practitioner Advanced Apprenticeship or Chartered Institute of Logistics and Transport certified certifications.

A good degree is a must if you're interested in a career as a transport and logistics professional. There are many courses that will help you expand your knowledge and improve your skills. The Chartered Institute of Logistics and Transport UK has a Level 2 Certificate for Transport and Logistics. This course is great for those just starting out in this field. A graduate recruitment program, offered by large logistics companies, can provide valuable work experience.

Locations

Many career options exist in the field of logistics and transportation. They involve planning and evaluating different distribution methods. These jobs require advanced analytical thinking and the ability handle complex data. It is also important to have good communication skills. You may need to travel to remote areas for some jobs. Graduate training schemes in transport and logistics are available, and they provide you with the skills needed to succeed in the field. Some of these programmes will also provide you with paid internships.

Transportation and logistics occupations are in high demand and are expected to grow 3% from 2019 to 2029, on par with the national average. Some jobs will see faster growth than others, like commercial and airline pilots. Other jobs in this sector include driver/sales workers and delivery truck drivers.

FAQ

How important is automation in manufacturing?

Automation is essential for both manufacturers and service providers. It allows them provide faster and more efficient services. It also helps to reduce costs and improve productivity.

How can we increase manufacturing efficiency?

The first step is to identify the most important factors affecting production time. Next, we must find ways to improve those factors. If you don’t know where to begin, consider which factors have the largest impact on production times. Once you've identified them, try to find solutions for each of those factors.

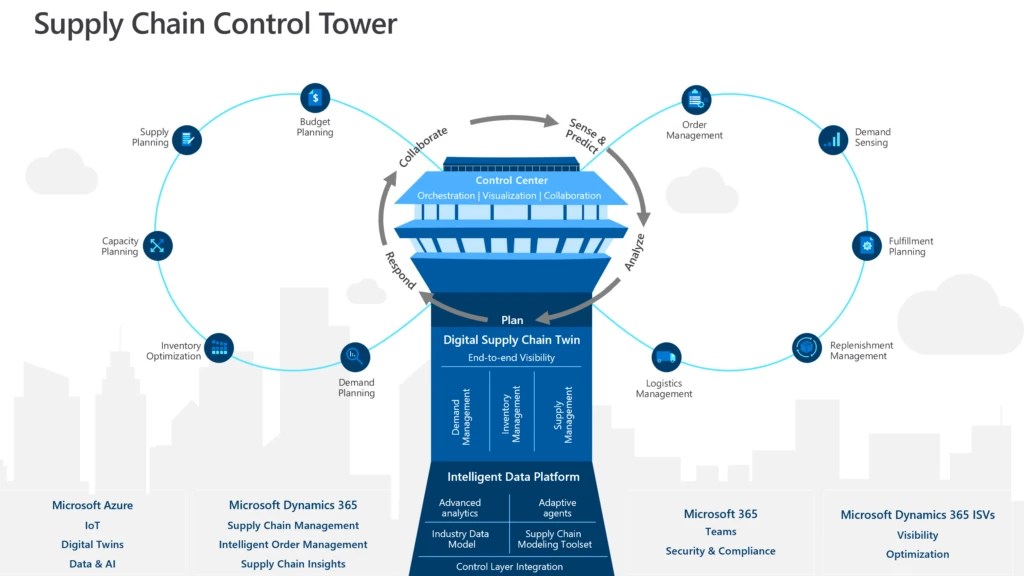

What are manufacturing and logistics?

Manufacturing is the process of creating goods from raw materials by using machines and processes. Logistics encompasses the management of all aspects associated with supply chain activities such as procurement, production planning, distribution and inventory control. It also includes customer service. Logistics and manufacturing are often referred to as one thing. It encompasses both the creation of products and their delivery to customers.

What does manufacturing industry mean?

Manufacturing Industries refers to businesses that manufacture products. Consumers are people who purchase these goods. These companies employ many processes to achieve this purpose, such as production and distribution, retailing, management and so on. These companies produce goods using raw materials and other equipment. This includes all types manufactured goods such as clothing, building materials, furniture, electronics, tools and machinery.

Statistics

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

External Links

How To

How to Use Six Sigma in Manufacturing

Six Sigma is defined by "the application SPC (statistical process control) techniques to achieve continuous improvements." Motorola's Quality Improvement Department in Tokyo, Japan developed Six Sigma in 1986. Six Sigma's core idea is to improve the quality of processes by standardizing and eliminating defects. Many companies have adopted Six Sigma in recent years because they believe that there are no perfect products and services. Six Sigma seeks to reduce variation between the mean production value. It is possible to measure the performance of your product against an average and find the percentage of time that it differs from the norm. If the deviation is excessive, it's likely that something needs to be fixed.

Understanding the dynamics of variability within your business is the first step in Six Sigma. Once you've understood that, you'll want to identify sources of variation. These variations can also be classified as random or systematic. Random variations are caused when people make mistakes. While systematic variations are caused outside of the process, they can occur. Random variations would include, for example, the failure of some widgets to fall from the assembly line. You might notice that your widgets always fall apart at the same place every time you put them together.

Once you have identified the problem, you can design solutions. The solution could involve changing how you do things, or redesigning your entire process. Once you have implemented the changes, it is important to test them again to ensure they work. If they don’t work, you’ll need to go back and rework the plan.