Manufacturing Phoenix is an Arizona business that supplies a wide range of products for the federal government. It also offers similar products to individuals and commercial clients. All production can be done in one location, with all resources located within a few feet of each others. The company also provides employment opportunities for disabled people for over 40 year. It employs about 70 people in its manufacturing unit.

Honeywell Aerospace

The Phoenix area is home to Honeywell Aerospace, an aerospace company that develops innovative transportation solutions. Honeywell Aerospace's products and services enhance flight safety, fuel efficiency, and runway traffic. These products are used by almost all commercial airlines. Honeywell Aerospace also developed technology that was crucial in the creation of 2001: A Space Odyssey. Honeywell Aerospace also manufactures systems for the International Space Station.

Honeywell created a Phoenix, Arizona reactive metal-alloy additive manufacturing facility in 2016. This facility converted an old flame spray facility to support production of parts made of titanium and aluminium alloys. Honeywell plans on producing Inconel 718-based parts in this facility by 2017. The facility has attracted more than $25million in investment from Honeywell.

Raytheon Technologies Corp.

Raytheon Technologies Corp., a multinational defense and aerospace conglomerate, is headquartered in Arlington Virginia. This company is one of largest producers of military equipment around the globe. Its products include aircraft, rockets, missiles, and more. Raytheon is not only a major aerospace and defense producer, but also develops advanced technologies that can be used commercially.

Raytheon has a long tradition in aerospace and defense. For example, the company's aerial navigation system division accounts for 27.4%. It also makes mechanical and electric systems for airplanes.

Benchmark Electronics

Benchmark Electronics is an Arizona-based contract electronics manufacturing company. The Phoenix-based ODM company employs over 13,000 people worldwide. The company is located in Tempe Marketplace, Scottsdale and Tempe. Gayla Delly recently was promoted to CEO.

The Phoenix manufacturing plant offers manufacturing services and vertically integrated engineering. Its capabilities include embedded electronics design, microwave and radio frequency components, as well as high-frequency circuits. It also provides aftermarket solutions. It serves a wide variety of customers within the defense, industrial and commercial aerospace markets.

FAQ

How can manufacturing efficiency improved?

First, identify the factors that affect production time. The next step is to identify the most important factors that affect production time. If you don’t know how to start, look at which factors have the greatest impact upon production time. Once you have identified the factors, then try to find solutions.

How can manufacturing avoid production bottlenecks

Avoiding production bottlenecks is as simple as keeping all processes running smoothly, from the time an order is received until the product ships.

This includes both quality control and capacity planning.

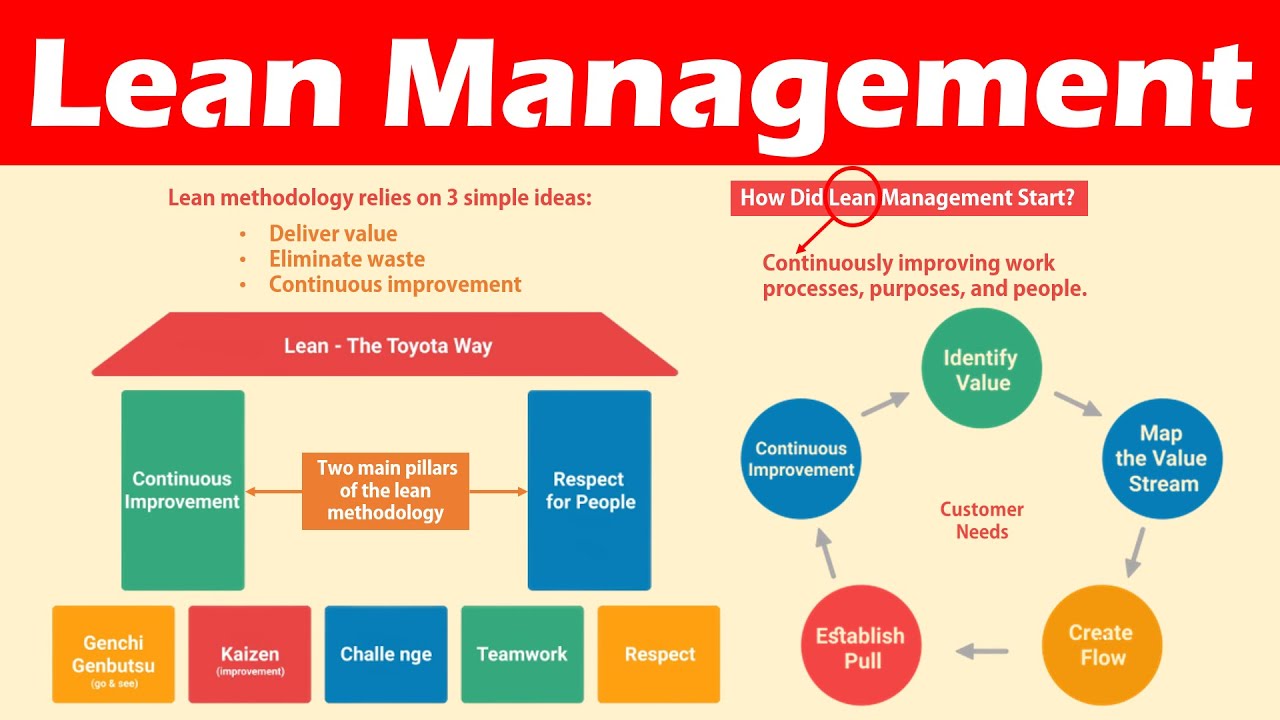

Continuous improvement techniques such Six Sigma are the best method to accomplish this.

Six Sigma can be used to improve the quality and decrease waste in all areas of your company.

It is focused on creating consistency and eliminating variation in your work.

What is meant by manufacturing industries?

Manufacturing Industries are businesses that produce products for sale. Consumers are people who purchase these goods. These companies employ many processes to achieve this purpose, such as production and distribution, retailing, management and so on. They manufacture goods from raw materials using machines and other equipment. This includes all types of manufactured goods, including food items, clothing, building supplies, furniture, toys, electronics, tools, machinery, vehicles, pharmaceuticals, medical devices, chemicals, and many others.

What does "warehouse" mean?

A warehouse is a place where goods are stored until they are sold. It can be an outdoor or indoor area. In some cases it could be both indoors and outdoors.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

How to Use Just-In-Time Production

Just-in-time (JIT) is a method that is used to reduce costs and maximize efficiency in business processes. This is where you have the right resources at the right time. This means that you only pay the amount you actually use. Frederick Taylor first coined this term while working in the early 1900s as a foreman. He noticed that workers were often paid overtime when they had to work late. He then concluded that if he could ensure that workers had enough time to do their job before starting to work, this would improve productivity.

The idea behind JIT is that you should plan ahead and have everything ready so you don't waste money. It is important to look at your entire project from beginning to end and ensure that you have enough resources to handle any issues that may arise. If you anticipate that there might be problems, you'll have enough people and equipment to fix them. This way, you won't end up paying extra money for things that weren't really necessary.

There are many JIT methods.

-

Demand-driven: This JIT is where you place regular orders for the parts/materials that are needed for your project. This will allow you to track how much material you have left over after using it. It will also allow you to predict how long it takes to produce more.

-

Inventory-based: This allows you to store the materials necessary for your projects in advance. This allows one to predict how much they will sell.

-

Project-driven: This means that you have enough money to pay for your project. If you know the amount you require, you can buy the materials you need.

-

Resource-based JIT is the most widespread form. You assign certain resources based off demand. You might assign more people to help with orders if there are many. If you don’t have many orders you will assign less people to the work.

-

Cost-based: This is a similar approach to resource-based but you are not only concerned with how many people you have, but also how much each one costs.

-

Price-based: This approach is very similar to the cost-based method except that you don't look at individual workers costs but the total cost of the company.

-

Material-based: This is quite similar to cost-based, but instead of looking at the total cost of the company, you're concerned with how much raw materials you spend on average.

-

Time-based JIT: This is another variant of resource-based JIT. Instead of focusing on how much each employee costs, you focus on how long it takes to complete the project.

-

Quality-based: This is yet another variation of resource-based JIT. Instead of thinking about how much each employee costs or how long it takes to manufacture something, you think about how good the quality of your product is.

-

Value-based JIT: This is the latest form of JIT. This is where you don't care about how the products perform or whether they meet customers' expectations. Instead, you're focused on how much value you add to the market.

-

Stock-based: This is an inventory-based method that focuses on the actual number of items being produced at any given time. It's useful when you want maximum production and minimal inventory.

-

Just-in-time planning (JIT): This is a combination JIT and supply-chain management. It refers to the process of scheduling the delivery of components as soon as they are ordered. It's important because it reduces lead times and increases throughput.