Michigan has some of the highest unemployment rates, both in the Midwest and the United States. In order to assist families during economic downturns, Unemployment Insurance was established. However, the system was not updated to meet today's workforce. Many of the state's policies are outdated, especially when it comes to protecting women and Black and Latinx workers.

Michigan's maximum weekly allowance has been increased only once since 1995. It is also the only state that offers less than 26 weeks of unemployment benefit. In reality, fewer than 10 weeks are provided, while a family may find that they fall into poverty if they lose a job before the maximum number of weeks is reached. Michigan is not doing enough to ensure all unemployed workers have unemployment insurance.

Michigan's minimum wage is another example. Workers must earn a minimum wage at least $5667 per week in order to be eligible for UI. This is more than the average midwestern wage. This is a good thing, but it leaves Michigan behind in the race for minimum wage.

The Advisory Council's "two thirds rule" states that Michigan's unemployment benefits should not exceed 50% of the average weekly wage. Instead, the state's maximum benefit is just 34%. Michigan is at a disadvantage in this area and should consider increasing its Unemployment Insurance. Wisconsin, Iowa and Pennsylvania offer maximum benefits which are at least 50% below the average wages.

Michigan's Unemployment Insurability program should be improved. This is a great way to reduce racial disparities and increase the safety net for all workers. In addition, the state should expand the period during which workers are eligible to apply for benefits. An extended base period is a great idea to increase federal funds for skills training, and reduce the cost of employment search. As an added bonus, it would improve the likelihood that more unemployed workers would get the assistance they need.

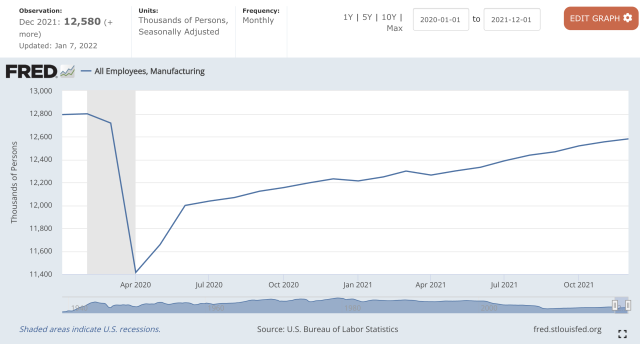

Michigan's unemployment rates have been declining steadily since 2009, despite being higher than in most other states. New figures from the state show that the unemployment rate is now at 6.1 percent as of January 2021. Since then, it has remained relatively steady. Michigan's unemployment rate was among the worst in the country during the recession. But, with strong investment in the unemployment insurance system, more people will be able get jobs before 26-weeks are reached.

The minimum wage that is required to qualify in the United States for unemployment benefits, which is available only in the Midwest, is the highest. In the same year, Michigan's maximum UI benefit is the lowest in the nation.

FAQ

Are there any Manufacturing Processes that we should know before we can learn about Logistics?

No. It doesn't matter if you don't know anything about manufacturing before you learn about logistics. Knowing about manufacturing processes will help you understand how logistics works.

Why is logistics so important in manufacturing?

Logistics is an integral part of every business. They are essential to any business's success.

Logistics plays a significant role in reducing cost and increasing efficiency.

What does it mean to warehouse?

A warehouse is a place where goods are stored until they are sold. It can be either an indoor or outdoor space. In some cases it could be both indoors and outdoors.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

Six Sigma and Manufacturing

Six Sigma is "the application statistical process control (SPC), techniques for continuous improvement." Motorola's Quality Improvement Department developed it at their Tokyo plant in Japan in 1986. Six Sigma's basic concept is to improve quality and eliminate defects through standardization. In recent years, many companies have adopted this method because they believe there is no such thing as perfect products or services. Six Sigma seeks to reduce variation between the mean production value. This means that if you take a sample of your product, then measure its performance against the average, you can find out what percentage of the time the process deviates from the norm. If you notice a large deviation, then it is time to fix it.

Understanding the nature of variability in your business is the first step to Six Sigma. Once you understand this, you can then identify the causes of variation. These variations can also be classified as random or systematic. Random variations are caused by human errors. Systematic variations can be caused by outside factors. These are, for instance, random variations that occur when widgets are made and some fall off the production line. It would be considered a systematic problem if every widget that you build falls apart at the same location each time.

After identifying the problem areas, you will need to devise solutions. This could mean changing your approach or redesigning the entire process. You should then test the changes again after they have been implemented. If they don't work you need to rework them and come up a better plan.