If you're looking for a good electronics component manufacturer, consider Murata Manufacturing Co., Ltd., a company based in Kyoto, Japan. Just by the name, you will know that this company has been around since more than 100 years. However, you should be familiarized with other companies. You'll find information about their products below. This company makes electronic components that are used in many types of electronics such as computers, printers, and home appliances.

Murata Manufacturing Co., Ltd.

Murata Manufacturing Co., Ltd., Japan is a Japanese component manufacturer. It makes electronic components, such as circuit boards and transistors. Continue reading to learn more about the company’s products. Learn more about Murata's manufacturing process. In addition, you can view some of Murata's most popular products. Visit Murata's website for more information.

Murata Energy Device Singapore Pte Ltd

The company's title means "Making Primary Batteries." This subsidiary is part of Murata Manufacturing Co. Ltd. in Japan, headquartered in Nagaokakyo. Murata Singapore, which was founded in 1972, is the oldest Murata factory outside Japan. Its mission it to supply electronics in South East Asia. Murata bought Sony Energy Devices Corporation in 2017. The company's headquarters is located at 1 Tuas Road, Singapore.

Murata Electronics Trading (Tianjin) Co. Ltd

Since 2007, Murata Elektrons Trading Company has been operating in Tianjin (China) as MEC. MEC is originally from Japan. It focuses its efforts on supplying high quality electronic parts to global markets. The company's operations have expanded to include sales of components that prevent EMI in the past few years. It also provides technical support services to customers with EMC-related problems.

Murata Vios

Murata Vios medical technology is moving onto hospital floors. Japanese firm is currently working on a monitoring system that detects early signs of clinical decay. The wireless system can be connected to Hicuity Health for clinical care oversight. It also engages specialists and bedside physicians in the event of patient deterioration. By combining these two technologies, Murata Vios is launching a custom offering to care providers and clinicians.

Integration of Murata Vios with PointClickCare

The Vios Monitoring System from Murata, Inc. has recently integrated with PointClickCare, a cloud-based senior care software vendor. This integration reduces transcription errors and data entry delays and improves clinician efficiency. Vios Monitoring System captures information such a heart rate and oxygen levels as well as pulse, respir rate, lung function, and posture data. This information is crucial for creating a patient-centric plan of care.

FAQ

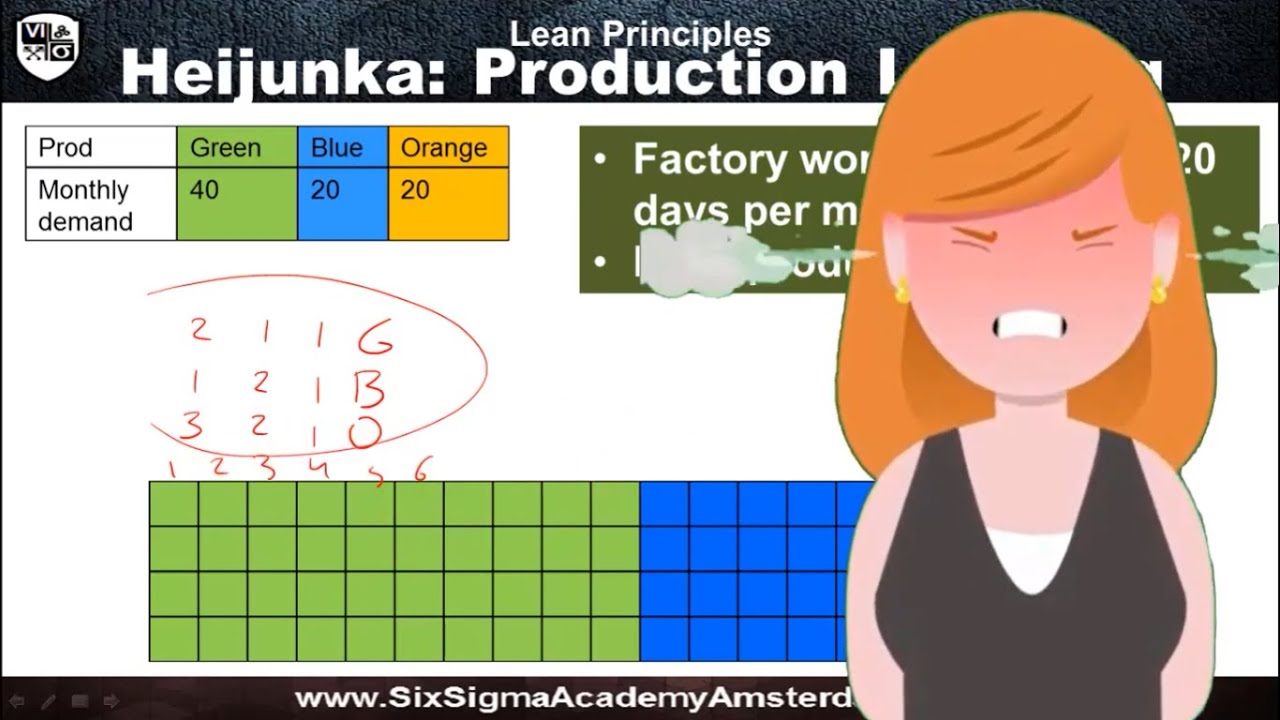

How can manufacturing reduce production bottlenecks?

The key to avoiding bottlenecks in production is to keep all processes running smoothly throughout the entire production cycle, from the time you receive an order until the time when the product ships.

This includes planning for both capacity requirements and quality control measures.

This can be done by using continuous improvement techniques, such as Six Sigma.

Six Sigma can be used to improve the quality and decrease waste in all areas of your company.

It seeks to eliminate variation and create consistency in your work.

How is a production manager different from a producer planner?

The main difference between a production planner and a project manager is that a project manager is usually the person who plans and organizes the entire project, whereas a production planner is mainly involved in the planning stage of the project.

What does it mean to warehouse?

A warehouse or storage facility is where goods are stored before they are sold. You can have it indoors or outdoors. In some cases it could be both indoors and outdoors.

What are the 7 Rs of logistics management?

The acronym "7R's" of Logistics stands for seven principles that underpin logistics management. It was developed by the International Association of Business Logisticians (IABL) and published in 2004 as part of its "Seven Principles of Logistics Management" series.

The acronym consists of the following letters:

-

Responsible - to ensure that all actions are within the legal requirements and are not detrimental to others.

-

Reliable - Have confidence in your ability to fulfill all of your commitments.

-

It is reasonable to use resources efficiently and not waste them.

-

Realistic - Consider all aspects of operations, including environmental impact and cost effectiveness.

-

Respectful - treat people fairly and equitably.

-

You are resourceful and look for ways to save money while increasing productivity.

-

Recognizable - provide customers with value-added services.

What does manufacturing mean?

Manufacturing Industries are those businesses that make products for sale. Consumers are people who purchase these goods. These companies use various processes such as production, distribution, retailing, management, etc., to fulfill this purpose. They manufacture goods from raw materials using machines and other equipment. This includes all types and varieties of manufactured goods, such as food items, clothings, building supplies, furnitures, toys, electronics tools, machinery vehicles, pharmaceuticals medical devices, chemicals, among others.

What skills should a production planner have?

To become a successful production planner, you need to be organized, flexible, and able to multitask. It is also important to be able communicate with colleagues and clients.

Do we need to know about Manufacturing Processes before learning about Logistics?

No. No. However, knowing about manufacturing processes will definitely give you a better understanding of how logistics works.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

How to Use 5S to Increase Productivity in Manufacturing

5S stands for "Sort", "Set In Order", "Standardize", "Separate" and "Store". The 5S methodology was developed at Toyota Motor Corporation in 1954. It allows companies to improve their work environment, thereby achieving greater efficiency.

This approach aims to standardize production procedures, making them predictable, repeatable, and easily measurable. This means that tasks such as cleaning, sorting, storing, packing, and labeling are performed daily. Through these actions, workers can perform their jobs more efficiently because they know what to expect from them.

Five steps are required to implement 5S: Sort, Set In Order, Standardize. Separate. Each step involves a different action which leads to increased efficiency. Sorting things makes it easier to find them later. When you arrange items, you place them together. Once you have separated your inventory into groups and organized them, you will store these groups in easily accessible containers. Finally, when you label your containers, you ensure everything is labeled correctly.

Employees will need to be more critical about their work. Employees must understand why they do certain tasks and decide if there's another way to accomplish them without relying on the old ways of doing things. To implement the 5S system, employees must acquire new skills and techniques.

In addition to improving efficiency, the 5S system also increases morale and teamwork among employees. As they begin to see improvements, they feel motivated to continue working towards the goal of achieving higher levels of efficiency.