Effective supply chains can impact all aspects within a business. Customer satisfaction, cost savings and growth of the business are all factors that can be improved by an effective supply chain. Regardless of the size of your business, the supply chain is an important factor in your success.

Supply chain management is one of the areas that are often overlooked by businesses, but it has a major impact on their overall performance. You will experience fewer delays, and you'll spend less on material shortages when your supply chain runs smoothly.

Successful supply chain control also increases customer satisfaction through the delivery of the right product in the right quantity at the appropriate time. Moreover, it improves profitability and the reputation of the company.

Since a very long time, businesses have sought to increase the speed of supply and reduce the costs. They have heavily invested in new technologies and infrastructure.

A number of studies show that a firm’s supply chain capabilities can have a profound effect on its financial and operational performance. They determine how efficiently the business runs and if it is capable of meeting its customers' needs and requirements.

If supply chain managers have the right training and a good understanding of their business from beginning to end, they can make the best decisions that will lead to savings. They can increase profit, improve customer service and build better relationships with suppliers by working closely together throughout the entire supply chain.

In a world of short product cycles and fast-moving markets, being able to adapt quickly is crucial. This means managing and analyzing raw inventory, transit time, and lead times of suppliers in real-time. The numbers must also be meaningful, accurate and granular.

Supply chain management must be able to assess the financial impact that one missed delivery could have. Additionally, they need to be prepared for the possibility of a shortage.

These backup plans will help them overcome unforeseen challenges. This will also give their competitors a competitive edge over them, as they lack flexible supply networks.

An effective and well-organized supply network is crucial to the success of any business. This allows the consumer to receive the products they need at the time that is most convenient for them.

Consideration of the different stages a product goes through during its life cycle is crucial when aligning your supply system with the manufacturing and distribution systems. This will enable you to design optimal supply-chain solutions that are tailored to the specific needs of each type of product and its stage in life.

A good strategy for supply chain will help ensure that an organisation can be adapted to its purpose, whether it's being responsive and agile, cost-effective and efficient or driven by innovation.

Organizational design of the supply chain function interacts with technology, assets, processes, and people in order to support business strategy. These elements must be aligned for a successful supply chain.

FAQ

What can I do to learn more about manufacturing?

Practical experience is the best way of learning about manufacturing. You can read books, or watch instructional videos if you don't have the opportunity to do so.

What is the job of a production plan?

Production planners ensure that all project aspects are completed on time, within budget and within the scope. They also ensure the quality of the product and service meets the client's requirements.

What are the products and services of logistics?

Logistics is the process of moving goods from one point to another.

They cover all aspects of transportation, such as packing, loading, transporting and unloading.

Logisticians make sure that the right product arrives at the right place at the correct time and in safe conditions. They assist companies with their supply chain efficiency through information on demand forecasts. Stock levels, production times, and availability.

They coordinate with vendors and suppliers, keep track of shipments, monitor quality standards and perform inventory and order replenishment.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

How to Use Lean Manufacturing for the Production of Goods

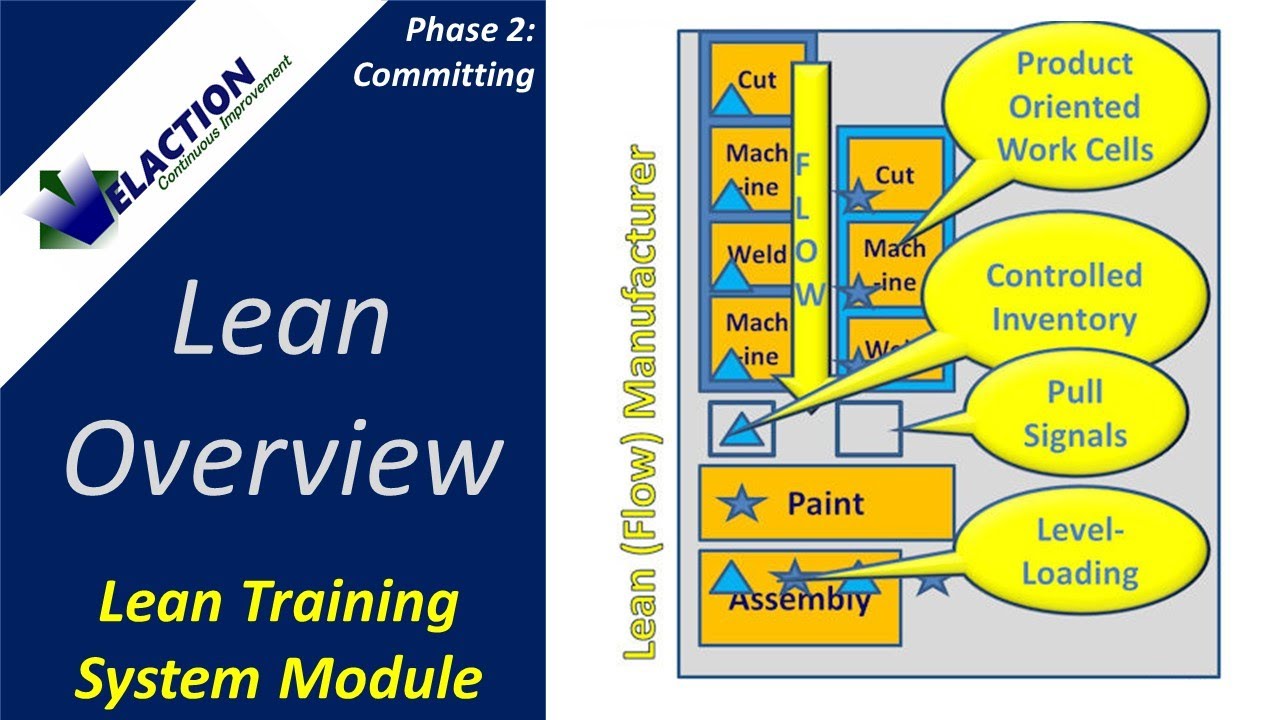

Lean manufacturing is a management style that aims to increase efficiency and reduce waste through continuous improvement. It was developed in Japan during the 1970s and 1980s by Taiichi Ohno, who received the Toyota Production System (TPS) award from TPS founder Kanji Toyoda. Michael L. Watkins published the original book on lean manufacturing, "The Machine That Changed the World," in 1990.

Lean manufacturing is often described as a set if principles that help improve the quality and speed of products and services. It emphasizes eliminating waste and defects throughout the value stream. The five-steps of Lean Manufacturing are just-in time (JIT), zero defect and total productive maintenance (TPM), as well as 5S. Lean manufacturing seeks to eliminate non-value added activities, such as inspection, work, waiting, and rework.

Lean manufacturing can help companies improve their product quality and reduce costs. Additionally, it helps them achieve their goals more quickly and reduces employee turnover. Lean manufacturing is considered one of the most effective ways to manage the entire value chain, including suppliers, customers, distributors, retailers, and employees. Lean manufacturing is widely used in many industries. Toyota's philosophy is a great example of this. It has helped to create success in automobiles as well electronics, appliances and healthcare.

Five principles are the basis of lean manufacturing:

-

Define Value - Identify the value your business adds to society and what makes you different from competitors.

-

Reduce Waste – Eliminate all activities that don't add value throughout the supply chain.

-

Create Flow - Make sure work runs smoothly without interruptions.

-

Standardize and simplify – Make processes as repeatable and consistent as possible.

-

Develop Relationships: Establish personal relationships both with internal and external stakeholders.

Lean manufacturing, although not new, has seen renewed interest in the economic sector since 2008. Many companies have adopted lean manufacturing methods to increase their marketability. Some economists even believe that lean manufacturing can be a key factor in economic recovery.

Lean manufacturing has many benefits in the automotive sector. These include higher customer satisfaction, lower inventory levels, lower operating expenses, greater productivity, and improved overall safety.

The principles of lean manufacturing can be applied in almost any area of an organization. Because it makes sure that all value chains are efficient and effectively managed, Lean Manufacturing is particularly helpful for organizations.

There are three main types of lean manufacturing:

-

Just-in Time Manufacturing (JIT), also known as "pull system": This form of lean manufacturing is often referred to simply as "pull". JIT is a process in which components can be assembled at the point they are needed, instead of being made ahead of time. This approach aims to reduce lead times, increase the availability of parts, and reduce inventory.

-

Zero Defects Manufacturing: ZDM ensures that no defective units leave the manufacturing plant. If a part needs to be fixed during the assembly line, it should be repaired rather than scrapped. This is also true for finished products that require minor repairs before shipping.

-

Continuous Improvement (CI),: Continuous improvement aims improve the efficiency and effectiveness of operations by continuously identifying issues and making changes to reduce waste. Continuous improvement refers to continuous improvement of processes as well people and tools.