Are you searching for a job in code? Here are some useful tips. Your resume must be professional and well-written. Showcase examples of your work that demonstrate your ability to write readable and efficient codes. Also, highlight your analytical skills and how those skills have benefitted past roles. Your past experience may be relevant to the salary range and skills required depending on what role you are applying. These are some great tips to help you create a coder's resume.

Job descriptions

To make the most of your coding job description, you need to understand how to write a compelling job description. First, understand the expectations of your employer and what you are looking for in a candidate. Once you've answered the questions, it is possible to go on to describe the duties and responsibilities for the programmer. Templates are available to help you do this. These templates offer information about the necessary skills, education, experience, as well as the educational requirements for the position.

Programming is one of the many careers in computer science. Computer programmers design software applications, integrate systems, and train end users. They create source code, analyze algorithms, modify operating systems, and write source-code. They work closely with computer operators, manufacturers, and other users of computer software to resolve problems. Code jobs descriptions should be clear, concise and simple to comprehend.

Salary ranges

If you are interested to code, it is essential that you know the salaries for different titles. The TCS (Title Code System) is a UC system-wide database of salary ranges and other pay information. This system will allow you to access the most up-to date information about all UC job codes, unrepresented and representative. You can use the search box to find the salary ranges for codes jobs by entering the job title or code.

In general, the highest paying cities for Coders are Berkeley, CA, San Mateo, CA, and Daly City, CA. These three cities outpace the national average by about $15,184 and $14,311 respectively. These cities are ranked second and 3rd on the list, respectively, for code jobs. It is important to note that there may be regional differences. San Mateo salaries, for example, are nearly twice the average salary of those in Berkeley.

Essential skills

While there are numerous code jobs available, these require a combination of computer programming and design skills. A web designer must be both artistic and technically minded. Additionally, you will need to have some experience using graphic design software. A lot of companies hire people who have a degree either in computer science or from bootcamps that teach coding. Take a course in computer programing to learn the skills you need. A portfolio of work is also helpful for a potential employer.

No matter what kind of job you have, all coders will need the same skills. These skills include problem-solving as well as expression. You should be capable of mastering a variety coding languages like JavaScript, Ruby on Railss, and Python. It is important to be able to work independently as well as in a group. The most important skill for any code job is communication. Most programmers work behind a computer but communication is crucial in many situations. Excellent communication skills are essential.

Career paths

Coder careers may be something you have considered if you are an aspiring coder. Fortunately, there are many different types of these jobs. If you are creative and love to combine your programming skills with creativity, a coding job may be the right fit for you. Data analysts are more adept at coding because they can analyze and gather data to provide actionable insights. There are many options, no matter how experienced you are.

Alternately, you could use your technical skills to do research and development. Many large tech companies allocate part of their profits towards high-risk projects and hire cross-disciplinary team members such as software developers, data scientists and business analysts. These positions are often highly competitive and require specialized skills. Some companies hire polyglots, founders and ethical hackers. It doesn't really matter what path you choose, but it's crucial to understand the career paths in your chosen field.

FAQ

How can manufacturing reduce production bottlenecks?

Avoiding production bottlenecks is as simple as keeping all processes running smoothly, from the time an order is received until the product ships.

This includes planning for capacity requirements as well as quality control measures.

Continuous improvement techniques like Six Sigma are the best way to achieve this.

Six Sigma is a management method that helps to improve quality and reduce waste.

It's all about eliminating variation and creating consistency in work.

What are the four types of manufacturing?

Manufacturing refers the process of turning raw materials into useful products with machines and processes. It includes many different activities like designing, building and testing, packaging, shipping and selling, as well as servicing.

What is production planning?

Production planning is the process of creating a plan that covers all aspects of production. This includes scheduling, budgeting and crew, location, equipment, props, and more. This document aims to ensure that everything is planned and ready when you are ready to shoot. It should also contain information on achieving the best results on set. This includes information on shooting times, locations, cast lists and crew details.

The first step in filming is to define what you want. You may have already decided where you would like to shoot, or maybe there are specific locations or sets that you want to use. Once you have identified the scenes and locations, you can start to determine which elements are required for each scene. If you decide you need a car and don't know what model to choose, this could be an example. To narrow your options, you can search online for available models.

After you have selected the car you want, you can begin to think about additional features. Are you looking for people to sit in the front seats? Maybe you need someone to move around in the back. You might want to change your interior color from black and white. These questions will help guide you in determining the ideal look and feel for your car. You can also think about the type of shots you want to get. You will be filming close-ups and wide angles. Maybe the engine or steering wheel is what you are looking to film. These details will help identify the exact car you wish to film.

Once you have determined all of the above, you can move on to creating a schedule. A schedule will tell you when you need to start shooting and when you need to finish. Each day will include the time when you need to arrive at the location, when you need to leave and when you need to return home. Everyone knows exactly what they should do and when. You can also make sure to book extra staff in advance if you have to hire them. There is no point in hiring someone who won't turn up because you didn't let him know.

When creating your schedule, you will also need to consider the number of days you need to film. Some projects can be completed in a matter of days or weeks. Others may take several days. When creating your schedule, be aware of whether you need more shots per day. Multiple takes at the same place will result in higher costs and longer completion times. You can't be certain if you will need multiple takes so it is better not to shoot too many.

Budgeting is another crucial aspect of production plan. Setting a realistic budget is essential as it will allow you to work within your means. You can always lower the budget if you encounter unexpected problems. But, don't underestimate how much money you'll spend. Underestimating the cost will result in less money after you have paid for other items.

Production planning is a complicated process. But once you understand how everything works together, it becomes much easier to plan future project.

What is the difference between Production Planning, Scheduling and Production Planning?

Production Planning (PP), or production planning, is the process by which you determine what products are needed at any given time. This is accomplished by forecasting the demand and identifying production resources.

Scheduling is the process that assigns dates to tasks so they can get completed within a given timeframe.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

How to Use lean manufacturing in the Production of Goods

Lean manufacturing is a management system that aims at increasing efficiency and reducing waste. It was developed in Japan during the 1970s and 1980s by Taiichi Ohno, who received the Toyota Production System (TPS) award from TPS founder Kanji Toyoda. The first book published on lean manufacturing was titled "The Machine That Changed the World" written by Michael L. Watkins and published in 1990.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It is about eliminating defects and waste from all stages of the value stream. Lean manufacturing is called just-in-time (JIT), zero defect, total productive maintenance (TPM), or 5S. Lean manufacturing seeks to eliminate non-value added activities, such as inspection, work, waiting, and rework.

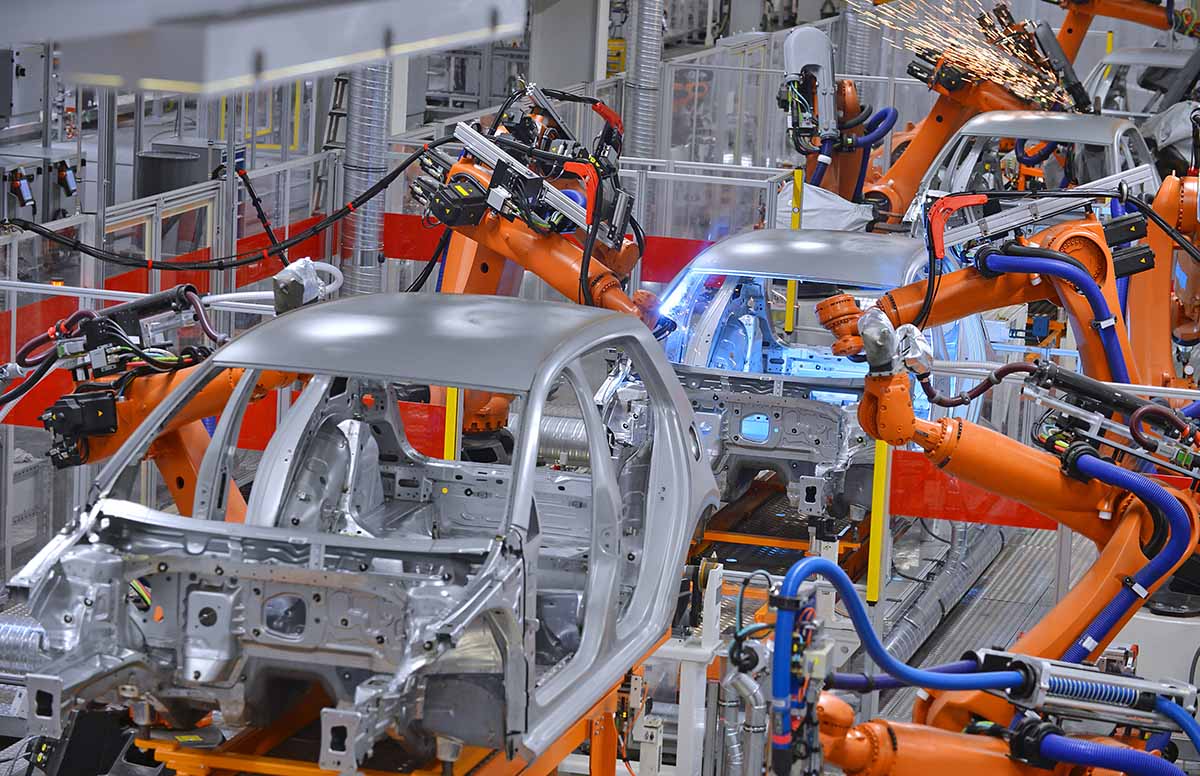

In addition to improving product quality and reducing costs, lean manufacturing helps companies achieve their goals faster and reduces employee turnover. Lean manufacturing can be used to manage all aspects of the value chain. Customers, suppliers, distributors, retailers and employees are all included. Lean manufacturing is widely used in many industries. Toyota's philosophy is the foundation of its success in automotives, electronics and appliances, healthcare, chemical engineers, aerospace, paper and food, among other industries.

Five principles are the basis of lean manufacturing:

-

Define value - Find out what your business contributes to society, and what makes it different from other competitors.

-

Reduce Waste – Eliminate all activities that don't add value throughout the supply chain.

-

Create Flow. Ensure that your work is uninterrupted and flows seamlessly.

-

Standardize and Simplify – Make processes as consistent, repeatable, and as simple as possible.

-

Building Relationships – Establish personal relationships with both external and internal stakeholders.

Although lean manufacturing isn't a new concept in business, it has gained popularity due to renewed interest in the economy after the 2008 global financial crisis. Many businesses have adopted lean manufacturing techniques to help them become more competitive. Economists think that lean manufacturing is a crucial factor in economic recovery.

Lean manufacturing is now becoming a common practice in the automotive industry, with many benefits. These include better customer satisfaction and lower inventory levels. They also result in lower operating costs.

Any aspect of an enterprise can benefit from Lean manufacturing. This is because it ensures efficiency and effectiveness in all stages of the value chain.

There are three main types in lean manufacturing

-

Just-in-Time Manufacturing: Also known as "pull systems", this type of lean manufacturing uses just-in-time manufacturing (JIT). JIT is a method in which components are assembled right at the moment of use, rather than being manufactured ahead of time. This approach is designed to reduce lead times and increase the availability of components. It also reduces inventory.

-

Zero Defects Manufacturing (ZDM): ZDM focuses on ensuring that no defective units leave the manufacturing facility. If a part is required to be repaired on the assembly line, it should not be scrapped. This applies to finished products, which may need minor repairs before they are shipped.

-

Continuous Improvement (CI): CI aims to improve the efficiency of operations by continuously identifying problems and making changes in order to eliminate or minimize waste. Continuous Improvement (CI) involves continuous improvement in processes, people, tools, and infrastructure.