As a study engineer, you use a combination of creativity and scientific analysis to design and create things that improve the world around us. You can improve the lives many people by designing bridges and medical equipment.

It's important to choose a course that suits your interests and abilities. Kingston University offers undergraduate degrees in chemical, civil and electrical engineering, among other engineering disciplines.

A bachelor's in engineering is a prerequisite for becoming a licensed engineer. It includes math, sciences and humanities coursework that can be applied in a wide range of career options.

Some engineers earn a master's or doctorate degree to specialize in a particular area. These can expand your career and enhance your job opportunities.

You can also choose to take a course that is specific to your industry, like oil and gas or mining. These courses will teach students how to evaluate the underground availability of metals, oil and other natural resources.

Manufacturing is a process by which raw materials are transformed into products to be sold in stores or markets. Learn the basics of production as well as how to plan, and then execute production lines.

As an engineer, you'll need to be able to work under pressure and handle a variety of responsibilities. You will also need to prioritize your tasks and manage your time to complete them in a limited time frame.

You'll want to select a college with an accredited engineering program if you plan on pursuing a degree in the field. This indicates that the college meets the standards set forth by ABET which accredits the engineering education programs of the United States.

You must attend college full time for four consecutive years and earn a minimum of sixty credit hours in each semester. Then, you must pass a test and gain work experience in your chosen engineering area.

The average salary of a Study Engineer is $94,463 a year. This includes a salary at the entry level of about $30 and a salary as a Senior Research Engineer of about $123,325 each year.

As a study engineer, you will be responsible for identifying and evaluating new technologies that can assist companies in producing more efficient and cheaper products. You will also develop designs and test prototypes to ensure their functionality, ease of use and durability. You may work with product development or marketing to refine products already on the market, or create new ones.

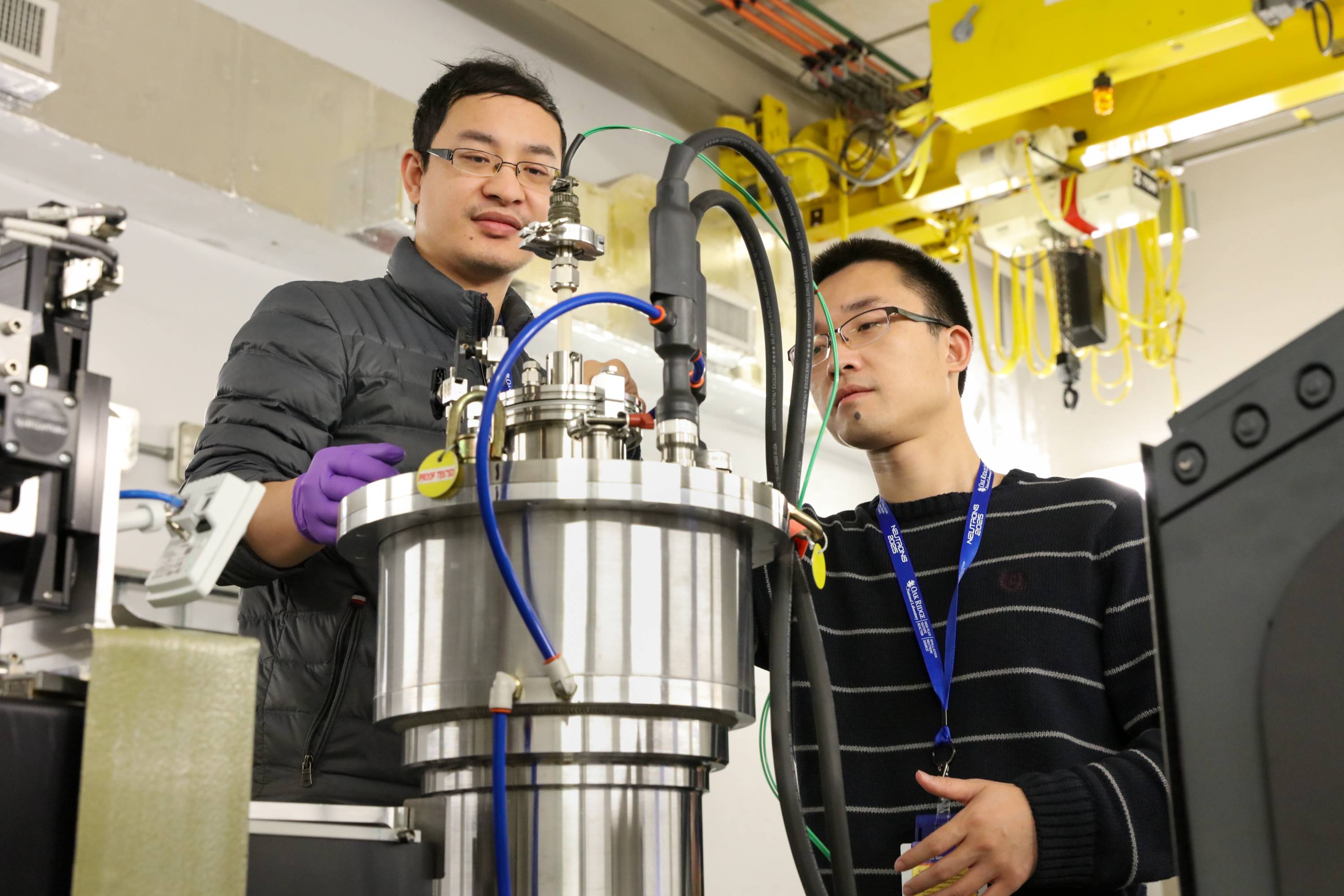

As a student engineer, you will be spending a considerable amount of time both in the lab as well as on the job. You will need to be able perform complex data analyses and have a solid grasp of the science behind engineering projects.

You must be passionate about science and enjoy solving problems. Also, you'll need to be familiar with physics, mathematics and chemistry.

The best way to prepare for a career in engineering is to pursue an accredited program and then take the FE exam after graduation. Then, you'll need to get some engineering work experience before taking the PE exam and getting licensed.

FAQ

What skills are required to be a production manager?

To become a successful production planner, you need to be organized, flexible, and able to multitask. It is also important to be able communicate with colleagues and clients.

What is production planning?

Production Planning is the creation of a plan to cover all aspects, such as scheduling, budgeting. Location, crew, equipment, props and other details. This document is designed to make sure everything is ready for when you're ready to shoot. It should also provide information about how best to produce the best results while on set. This includes information on shooting times, locations, cast lists and crew details.

The first step is to outline what you want to film. You may already know where you want the film to be shot, or perhaps you have specific locations and sets you wish to use. Once you have identified your locations and scenes it's time to begin figuring out what elements you will need for each one. You might decide you need a car, but not sure what make or model. You could look online for cars to see what options are available, and then narrow down your choices by selecting between different makes or models.

After you have selected the car you want, you can begin to think about additional features. You might need to have people in the front seats. Maybe you need someone to move around in the back. Perhaps you would like to change the interior colour from black to white. These questions will help determine the look and feel you want for your car. The type of shots that you are looking for is another thing to consider. Will you be filming close-ups or wide angles? Maybe you want the engine or the steering wheels to be shown. This will allow you to determine the type of car you want.

Once you have established all the details, you can create a schedule. You can create a schedule that will outline when you must start and finish your shoots. The schedule will show you when to get there, what time to leave, and when to return home. Everyone will know what they need and when. If you need to hire extra staff, you can make sure you book them in advance. You don't want to hire someone who won't show up because he didn't know.

It is important to calculate the amount of filming days when you are creating your schedule. Some projects only take one or two days, while others may last weeks. When you are creating your schedule, you should always keep in mind whether you need more than one shot per day or not. Shooting multiple takes over the same location will increase costs and take longer to complete. You can't be certain if you will need multiple takes so it is better not to shoot too many.

Budget setting is another important aspect in production planning. As it will allow you and your team to work within your financial means, setting a realistic budget is crucial. It is possible to reduce the budget at any time if you experience unexpected problems. You shouldn't underestimate the amount you'll spend. If you underestimate the cost of something, you will have less money left after paying for other items.

Production planning is a complicated process. But once you understand how everything works together, it becomes much easier to plan future project.

What are manufacturing and logistic?

Manufacturing refers to the process of making goods using raw materials and machines. Logistics encompasses the management of all aspects associated with supply chain activities such as procurement, production planning, distribution and inventory control. It also includes customer service. Manufacturing and logistics are often considered together as a broader term that encompasses both the process of creating products and delivering them to customers.

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

How to Use the 5S to Increase Productivity In Manufacturing

5S stands to stand for "Sort", “Set In Order", “Standardize", and "Store". Toyota Motor Corporation created the 5S methodology in 1954. This methodology helps companies improve their work environment to increase efficiency.

The idea behind standardizing production processes is to make them repeatable and measurable. Cleaning, sorting and packing are all done daily. These actions allow workers to perform their job more efficiently, knowing what to expect.

Five steps are required to implement 5S: Sort, Set In Order, Standardize. Separate. Each step involves a different action which leads to increased efficiency. Sorting things makes it easier to find them later. When items are ordered, they are put together. Next, organize your inventory into categories and store them in containers that are easily accessible. Finally, label all containers correctly.

Employees must be able to critically examine their work practices. Employees need to understand the reasons they do certain jobs and determine if there is a better way. To implement the 5S system, employees must acquire new skills and techniques.

In addition to increasing efficiency, the 5S method also improves morale and teamwork among employees. As they begin to see improvements, they feel motivated to continue working towards the goal of achieving higher levels of efficiency.