The Department of Energy is the federal agency that administers energy policy and manages the United States' nuclear infrastructure. They also oversee scientific research related to energy and environment. Below are some of their programs. The Office of Fossil Energy develops policy on the use of natural gas, coal, and electric energy. The Nuclear Weapons Program oversees nuclear reactor production for the United States Navy. Below is a list of programs in the Department of Energy.

Office of Fossil Energy is responsible for developing policies on the use of natural gases, coal, electric, and other fossil energy sources.

The Department of the Interior houses the Office of Fossil Energy. It is responsible to develop policies that govern the use of natural and fossil energy, such as coal and electricity. These policies are developed and directed by the OFE, which also directs projects that increase energy efficiency. The agency also works with existing power plants to reduce their carbon footprint, which can contribute to global climate change. Fossil fuels account for 85% of our country's energy supply, and the OFE works to limit their use.

Office of Energy Research pioneered facilities and research projects

The Office of Energy Research has pioneered research and facilities projects for the Department of Energy. It is responsible for the creation of the Human Genome Project, the Global Climate Change Program, and many other large-scale research facilities. The Office is a pioneer in accelerator science.

Office of Nuclear Weapons Policy has policies to govern the use of nuclear weapons

The Office of Nuclear Weapons Policy (ONWP) is responsible for developing policies concerning the use of nuclear weapons in the Department of Energy. Its main responsibility is to develop and assess nuclear weapon policies. Nuclear weapons are a dangerous form of military force, so they must be used carefully. Some analysts have raised concerns about the plans of the administration and have also raised their own questions. Some critics are skeptical about the need for more than 2,200 warheads to be deployed in the forces. While others believe Russia is the only threat with enough targets that it warrants wide-spread attack on its nukes, others disagree.

U.S. Navy has nuclear reactor production under control thanks to its nuclear weapons program

Many components are part of the U.S. Nuclear Weapons Program. Many components support other military missions. The U.S. tactical bomber performs an important mission. However, it is not capable of flying airborne alert with nuclear missiles today. Until the 1990s, strategic bombers were not equipped with quick-reaction strips. But, the U.S. maintains a stockpile nuclear weapons.

Since 1990 Office of Energy Research has been listed on the Government Accountability Office Top-Risk List

Since its inclusion on the list, the Department of Energy has faced a long and arduous road to restore trust and confidence. GAO has worked hard to improve public services and performance by addressing those issues that are causing the agency's failure to live up to its expectations. Some areas have been removed, but others are still high-risk. Here's a summary of what the High-Risk Report considers the most pressing issues facing today's government.

FAQ

What are the goods of logistics?

Logistics refers to all activities that involve moving goods from A to B.

They include all aspects associated with transport including packaging, loading transporting, unloading storage, warehousing inventory management customer service, distribution returns and recycling.

Logisticians ensure the product reaches its destination in the most efficient manner. They provide information on demand forecasts as well stock levels, production schedules and availability of raw material.

They also keep track of shipments in transit, monitor quality standards, perform inventories and order replenishment, coordinate with suppliers and vendors, and provide support services for sales and marketing.

What is production planning?

Production Planning is the creation of a plan to cover all aspects, such as scheduling, budgeting. Location, crew, equipment, props and other details. It is important to have everything ready and planned before you start shooting. This document should include information about how to achieve the best results on-set. It should include information about shooting locations, casting lists, crew details, equipment requirements, and shooting schedules.

The first step is to decide what you want. You may already know where you want the film to be shot, or perhaps you have specific locations and sets you wish to use. Once you have identified your locations and scenes, you can start working out which elements you require for each scene. One example is if you are unsure of the exact model you want but decide that you require a car. You could look online for cars to see what options are available, and then narrow down your choices by selecting between different makes or models.

After you have chosen the right car, you will be able to begin thinking about accessories. What about additional seating? You might also need someone to help you get around the back. You may want to change the interior's color from black or white. These questions will help you determine the exact look and feel of your car. The type of shots that you are looking for is another thing to consider. What type of shots will you choose? Maybe you want the engine or the steering wheels to be shown. These details will help identify the exact car you wish to film.

Once you have determined all of the above, you can move on to creating a schedule. The schedule will show you when to begin shooting and when to stop. You will need to know when you have to be there, what time you have to leave and when your return home. Everyone knows exactly what they should do and when. If you need to hire extra staff, you can make sure you book them in advance. You don't want to hire someone who won't show up because he didn't know.

You will need to factor in the days that you have to film when creating your schedule. Some projects are quick and easy, while others take weeks. You should consider whether you will need more than one shot per week when creating your schedule. Multiple takes at the same place will result in higher costs and longer completion times. It's better to be safe than sorry and shoot less takes if you're not certain whether you need more takes.

Budget setting is an important part of production planning. It is important to set a realistic budget so you can work within your budget. Keep in mind that you can always reduce your budget if you face unexpected difficulties. It is important to not overestimate how much you will spend. If you underestimate the cost of something, you will have less money left after paying for other items.

Production planning can be a complex process. However, once you know how everything works together it will become easier to plan future projects.

How can we improve manufacturing efficiency?

The first step is to determine the key factors that impact production time. The next step is to identify the most important factors that affect production time. If you aren't sure where to begin, think about the factors that have the greatest impact on production time. Once you have identified them, it is time to identify solutions.

What are manufacturing & logistics?

Manufacturing is the production of goods using raw materials. Logistics manages all aspects of the supply chain, including procurement, production planning and distribution, inventory control, transportation, customer service, and transport. As a broad term, manufacturing and logistics often refer to both the creation and delivery of products.

What is the job of a manufacturer manager?

Manufacturing managers must ensure that manufacturing processes are efficient, effective, and cost-effective. They should also be aware and responsive to any company problems.

They must also be able to communicate with sales and marketing departments.

They must also keep up-to-date with the latest trends in their field and be able use this information to improve productivity and efficiency.

What does "warehouse" mean?

A warehouse or storage facility is where goods are stored before they are sold. It can be indoors or out. It may also be an indoor space or an outdoor area.

What are the essential elements of running a logistics firm?

To be a successful businessman in logistics, you will need many skills and knowledge. For clients and suppliers to be successful, you need to have excellent communication skills. It is important to be able to analyse data and draw conclusions. You must be able and able to handle stress situations and work under pressure. You must be creative and innovative to develop new ideas to improve efficiency. You will need strong leadership skills to motivate and direct your team members towards achieving their organizational goals.

To meet tight deadlines, you must also be efficient and organized.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

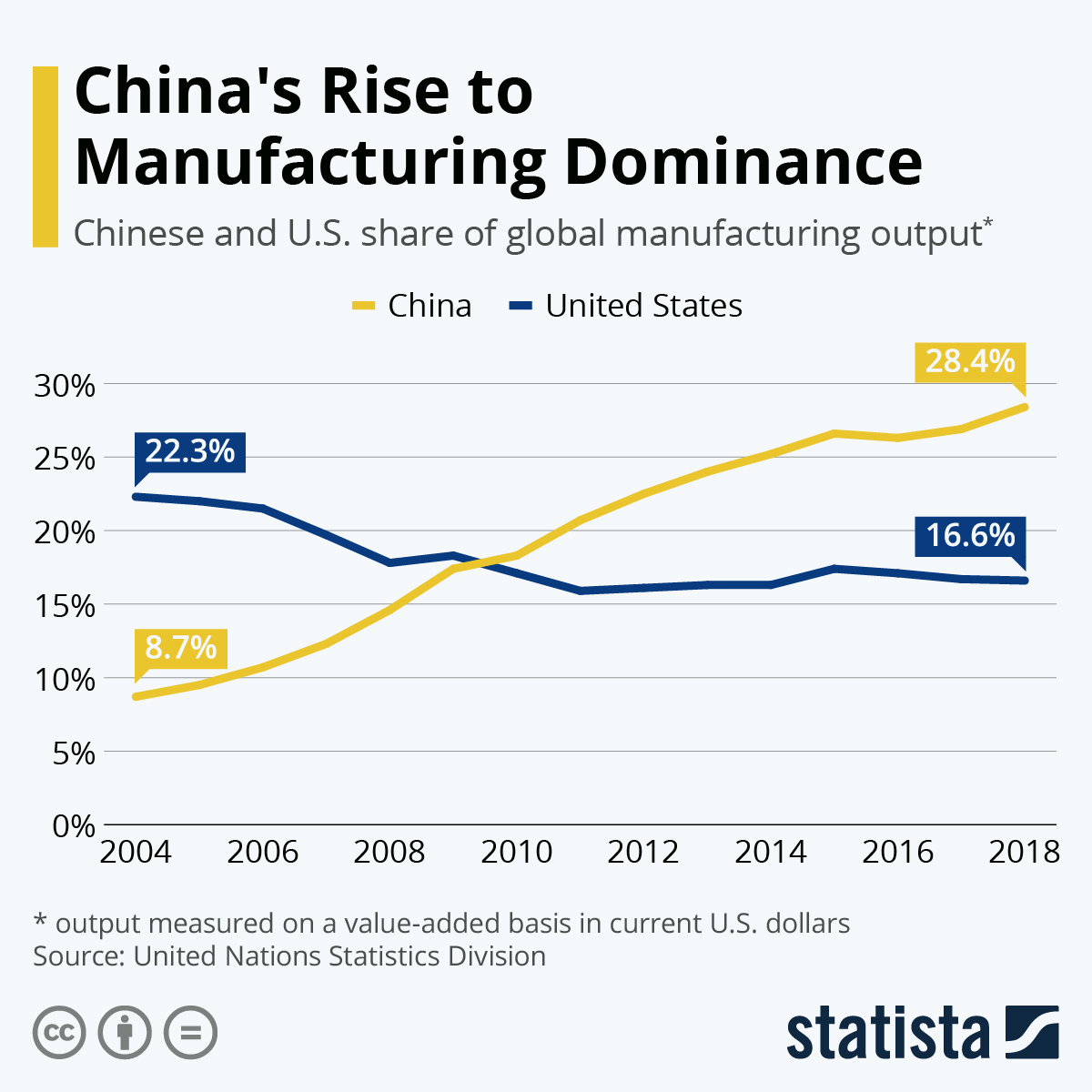

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

Six Sigma: How to Use it in Manufacturing

Six Sigma is defined as "the application of statistical process control (SPC) techniques to achieve continuous improvement." Motorola's Quality Improvement Department created Six Sigma at their Tokyo plant, Japan in 1986. Six Sigma's basic concept is to improve quality and eliminate defects through standardization. Since there are no perfect products, or services, this approach has been adopted by many companies over the years. Six Sigma aims to reduce variation in the production's mean value. This means that if you take a sample of your product, then measure its performance against the average, you can find out what percentage of the time the process deviates from the norm. If it is too large, it means that there are problems.

Understanding the nature of variability in your business is the first step to Six Sigma. Once you have a good understanding of the basics, you can identify potential sources of variation. It is important to identify whether the variations are random or systemic. Random variations occur when people make mistakes; systematic ones are caused by factors outside the process itself. Random variations would include, for example, the failure of some widgets to fall from the assembly line. But if you notice that every widget you make falls apart at the exact same place each time, this would indicate that there is a problem.

Once you've identified the problem areas you need to find solutions. It might mean changing the way you do business or redesigning it entirely. After implementing the new changes, you should test them again to see if they worked. If they didn't work, then you'll need to go back to the drawing board and come up with another plan.